XISKO-KK Series steel modules offer high rigidity, compact design, and seamless integration for automation. With widths from 40–86mm and strokes to 940mm, they support multi-axis setups. Finite element-optimized tracks ensure reliability in precision machinery, robotics, and lithium battery production. Options include telescopic covers, precision guides, and ball screw leads.

XISKO-KK Series steel modules combine high rigidity, lightweight construction, and precision engineering for industrial automation. Available in widths of 40mm (KK40K), 50mm (KK50K), 60mm (KK60K), and 86mm (KK86K), these modules support track lengths up to 940mm and multi-slide configurations. Key features include easy installation, optimized rigidity via finite element analysis, and compatibility with ball screw leads (1–20mm).

Applications include precision CNC equipment, automated assembly lines, and lithium battery manufacturing. Options cover motor integration (with/without brakes), aluminum/telescopic covers, and precision grades (P/C). The modules withstand demanding environments with oil scrapers and grease ports, ensuring long-term stability. Custom motor flanges (Mitsubishi, Panasonic) and guide block types (Standard A, Light Load S) enhance flexibility for robotics and material handling.

Key features include:

The track structure is analyzed by finite element rail analysis to obtain the best rigidity and quality.

- > Small size, light weight, easy to install and maintain

- > High rigidity, high precision, strong reliability

- > High wear resistance, long life

| Model | Track length | Positioning repeatability | Positioning precision | Travel parallelism | Maximum starting torque (N-cm) | ||||

| Precision | Criterion | Precision | Criterion | Precision | Criterion | Precision | Criterion | ||

| KK40K | 100 | ±0.003 | ±0.01 | 0.02 | – | 0.01 | – | 1.2 | 0.8 |

| 150 | |||||||||

| 200 | |||||||||

| KK50K | 150 | ±0.003 | ±0.01 | 0.02 | – | 0.01 | – | 4 | 2 |

| 200 | |||||||||

| 250 | |||||||||

| 300 | |||||||||

| KK60K | 150 | ±0.003 | ±0.01 | 0.02 | – | 0.01 | – | 15 | 7 |

| 200 | |||||||||

| 300 | |||||||||

| 400 | |||||||||

| 500 | ±0.003 | ±0.01 | 0.025 | – | 0.015 | – | 15 | 7 | |

| 600 | |||||||||

| KK86K | 340 | ±0.003 | ±0.01 | 0.025 | – | 0.015 | – | 15 | 10 |

| 440 | |||||||||

| 540 | |||||||||

| 640 | |||||||||

| 740 | ±0.003 | ±0.01 | 0.03 | – | 0.02 | – | 17 | 10 | |

| 940 | ±0.003 | ±0.01 | 0.04 | – | 0.03 | – | 25 | 10 | |

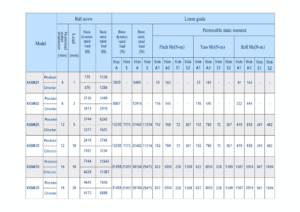

| Model | Ball screw lead (mm) | Track length L2 (mm) | Speed(mm/sec) | |

| Precision | Criterion | |||

| KK40K | 01 | 100 | 190 | 190 |

| 150 | 190 | 190 | ||

| 200 | 190 | 190 | ||

| KK50K | 02 | 150 | 270 | 270 |

| 200 | 270 | 270 | ||

| 250 | 270 | 270 | ||

| 300 | 270 | 270 | ||

| KK60K | 05 | 150 | 550 | 390 |

| 200 | 550 | 390 | ||

| 300 | 550 | 390 | ||

| 400 | 550 | 390 | ||

| 500 | 550 | 390 | ||

| 600 | 340 | 340 | ||

| 10 | 150 | 1100 | 790 | |

| 200 | 1100 | 790 | ||

| 300 | 1100 | 790 | ||

| 400 | 1100 | 790 | ||

| 500 | 1100 | 790 | ||

| 600 | 670 | 670 | ||

| KK86K | 10 | S40 | 740 | 520 |

| 440 | 740 | 520 | ||

| 540 | 740 | 520 | ||

| 640 | 740 | 520 | ||

| 740 | 740 | 520 | ||

| 940 | 610 | 430 | ||

| 20 | S40 | 1480 | 1050 | |

| 440 | 1480 | 1050 | ||

| 540 | 1480 | 1050 | ||

| 640 | 1480 | 1050 | ||

| 740 | 1480 | 1050 | ||

| 940 | 1220 | 870 | ||

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 13316792275

Bellona@shiguanglaser.com

+86 13430982872

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.