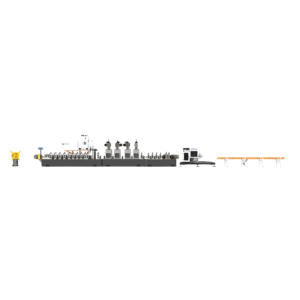

WZ-70P / 70K Series Compact 3D Tube Laser Cutters

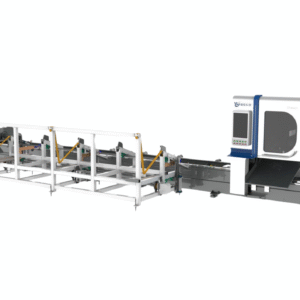

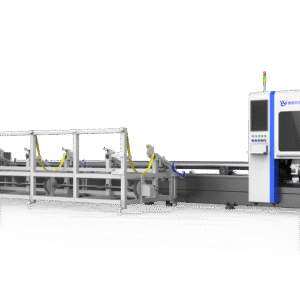

Unleash creative freedom with the Weizhuo WZ-70P/70K, a 3D tube fiber laser cutting system designed for complex part manufacturing. Featuring a cutting head with infinite rotation (W1 Axis) and an automated loading system, it effortlessly cuts intricate patterns, holes, and profiles on the surface of tubes. Ideal for industries like fitness equipment, furniture, and automotive, this machine transforms complex 3D drawings into finished parts with exceptional speed and precision.

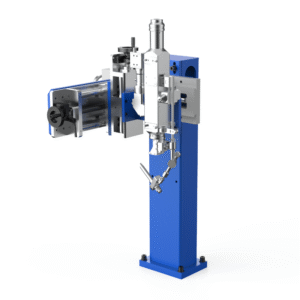

The Weizhuo WZ-70P/70K Series is engineered to move beyond simple cutting and into the realm of true three-dimensional fabrication. Its key feature is the advanced cutting head mounted on a W1 axis with infinite rotation, allowing it to perform complex machining operations around the entire circumference of a tube without stopping or resetting. This capability, combined with a specialized 3D pipe cutting system, makes it easy to import STEP or IGES files and produce intricate parts directly.

The system is fully automated, from the bundle loading rack to the finished part collection. This “lights-out” operational capability makes it a highly productive asset for producing parts with complex joinery, artistic patterns, or functional holes and slots.

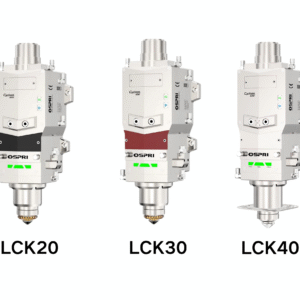

Engineered for intricate cuts on round, square, and rectangular tubes (5×5–120×120mm), the WZ-70P combines 1500W–6000W laser power with a 3-axis moving head. Its modular auto-feeding rack and 70mm chuck enable rapid material handling, while Ospri cutting heads and Xisko modules ensure smooth beveling and piercing. The Bai Chu control system minimizes setup time, making it optimal for HVAC, bicycle frames, and architectural metalwork.

✅ True 3D Cutting Capability:

Performs complex cutting paths, intersecting lines, and profiles anywhere on the tube surface.

✅ W1 Axis with Infinite Rotation:

Enables seamless, continuous cutting around the tube, perfect for intricate patterns and avoiding start/stop marks.

✅ Fully Automated Production:

Includes an automatic feeding rack and an intelligent control system for a complete, unattended production solution.

✅ High-Speed Positioning:

With single-axis speeds of 60m/min and a rotation speed of 75rpm, it maintains high throughput even on complex jobs.

✅ Direct 3D Software Integration:

Natively supports common 3D CAD formats like STEP and IGES, simplifying the transition from design to production.

✅ High-Precision Rotation:

Achieves a repetitive positioning accuracy of the rotation axis within <±10 Arcminutes, ensuring all features are perfectly aligned.

| Specification | Parameter |

|---|---|

| Equipment Model | WZ-70P/70K |

| Rated Output Power | 1500W (Optional) |

| Beam Quality | < 0.373 mrad |

| Laser Wavelength | 1070 nm |

| Maximum Cutting Thickness of Carbon Steel Pipes | < 2mm |

| Effective Cutting Of Pipe Diameter | φ10–64mm (10–85) |

| X-Axis Travel | 100mm |

| Y-Axis Travel | 100mm |

| Z-Axis Travel | 100mm |

| W1 Axis Travel | Infinite Rotation |

| Rotation Axis Positioning Accuracy | < ±20 Arcminutes |

| Repetitive Positioning Accuracy Of Rotation Axis | < ±10 Arcminutes |

| Maximum Positioning Speed (X, Y, Z Axis) | 60 m/min |

| W1 Axis Maximum Positioning Speed | 75 rpm |

| Cutting System | Three-Dimensional Pipe Special System |

| Support 3D Drawing Software | UG |

| Support Graphic Formats | Step, Iges, etc. |

| Electricity Demand | 380V / 50Hz / 100A |

| Cutting Gas Requirements | Oxygen, Nitrogen or Air |

| Requirements For Cutting Air Pressure | > 13kg |

| Main components | Model specifications | Unit | Quantity | Brand |

|---|---|---|---|---|

| Fiber Laser | Bfl-Cw1500t-A (Optional) | unit | 1 | Kipling / Chuangxin |

| Cutting Head | LC218S-S-Cep-31b-H04 | set | 1 | Ospri |

| Pipe Cutting System | set | 1 | Bai Chu / Wei Hong | |

| Servo | set | 6 | Delta / Hechuan | |

| Special Cabinet | set | 1 | Weizhuo | |

| Electronic Control | set | 1 | Weizhuo | |

| Cooling-Water Machine | 1.5p | set | 1 | Ice source |

| Automatic Feeding Rack | set | 1 | Weizhuo | |

| Module | set | 4 | Xisko | |

| Chuck | 70mm | set | 1 | Customized |

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.