FAQs

Our Help Center - Frequently Asked Questions For Service.

Product & Technical FAQs

How do I choose the right laser machine for my needs?

Provide details like material type (metal/alloy), thickness, desired cutting/welding area, and production volume. Our experts will recommend optimized configurations.

Do you accept OEM/ODM requests?

Yes. We offer branding (logo/logo-free), customized specifications, and private labeling.

What types of laser machines do you offer?

We specialize in fiber laser cutting machines, laser welding machines, laser cleaning machines, and metal laser cutting-welding-cleaning-rust removing combo machines. Applications span tube/pipe, sheet metal processing, automotive, aerospace, and more.

Can your machines handle thick materials?

Yes. High-power models (6kW–20kW) can cut stainless steel up to 30mm and aluminum up to 20mm. Custom solutions are available for specialized projects.

What materials can your lasers process?

Carbon steel, stainless steel, aluminum, brass, copper, titanium, and alloys. Non-metal materials like wood/PVC require specific machines (contact us for details).

What’s the difference between CO₂ and fiber lasers?

Fiber lasers are ideal for metals (faster, more efficient, lower maintenance). CO₂ lasers handle non-metals and thin metals but consume more power.

Are your machines compatible with CNC systems?

Yes, all models integrate with standard CNC controls for automated precision. We also offer custom integration services.

Do you provide technical documentation for machines?

Yes, including user manuals, maintenance guides, and video tutorials in multiple languages.

Purchase & Payment FAQs

What’s the minimum order quantity (MOQ)?

Stock items have no MOQ. Custom orders require a minimum quantity based on production costs—contact us for a tailored quote.

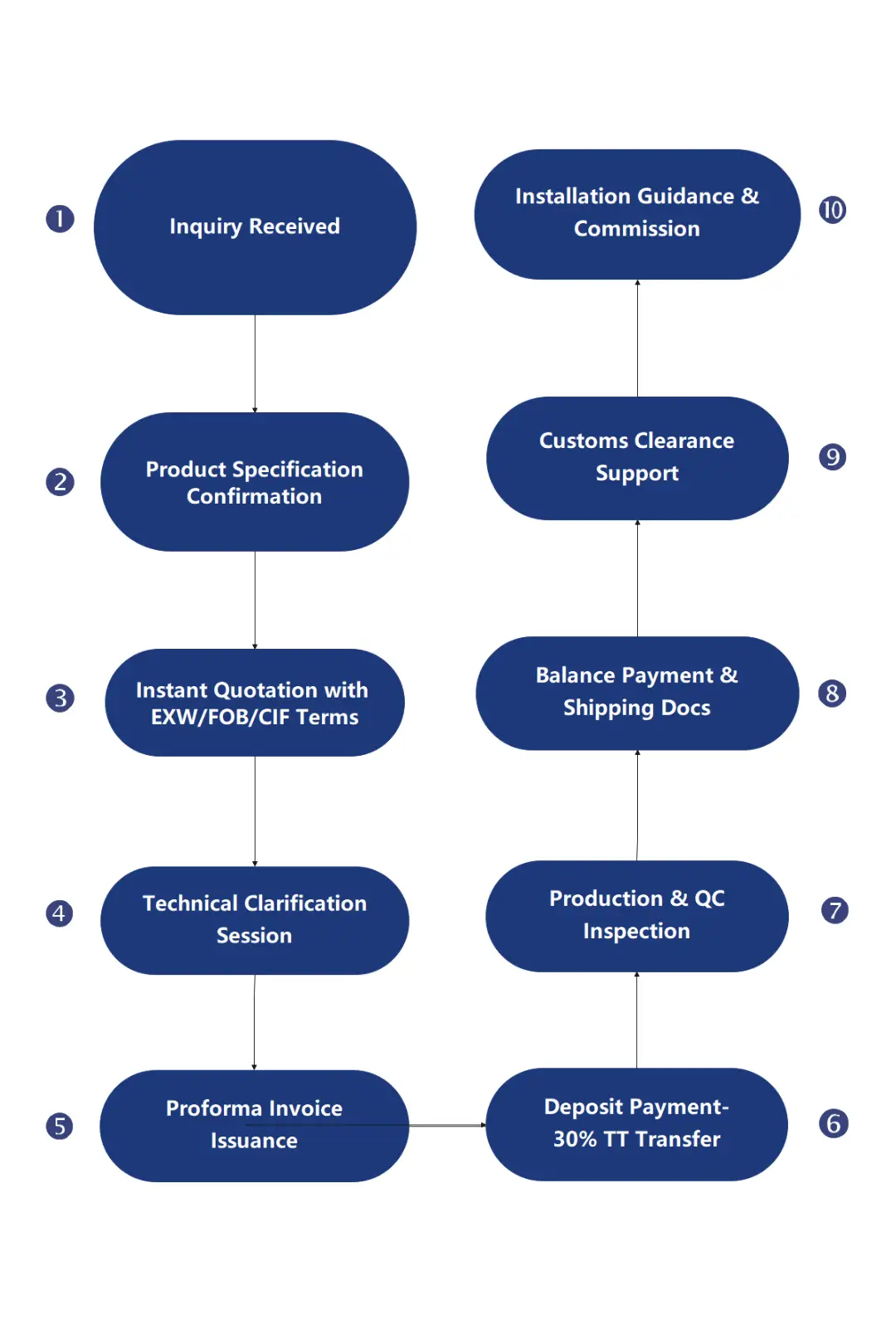

What payment methods do you accept?

T/T (30% deposit, 70% balance before shipment), L/C, PayPal (for samples/orders <$5,000), and trade assurance via Alibaba.

How long does it take to deliver?

Standard delivery time is 30-45 days after order confirmation. Urgent orders can be delivered in expedited service (15-20 days). In-stock products are generally shipped within three days after receiving payment. The delivery time depends on the transportation method and destination country.

Do you offer free trials or sample testing?

Yes. Send us your material samples (≥3pcs, ≥600mm length) for free cutting/welding tests. Results and reports will be shared promptly.

What materials can your lasers process?

Carbon steel, stainless steel, aluminum, brass, copper, titanium, and alloys. Non-metal materials like wood/PVC require specific machines (contact us for details).

What’s the difference between CO₂ and fiber lasers?

Fiber lasers are ideal for metals (faster, more efficient, lower maintenance). CO₂ lasers handle non-metals and thin metals but consume more power.

Are your machines compatible with CNC systems?

Yes, all models integrate with standard CNC controls for automated precision. We also offer custom integration services.

Do you provide technical documentation for machines?

Yes, including user manuals, maintenance guides, and video tutorials in multiple languages.

After-Sales & Support FAQs

What if my machine malfunctions?

Contact us immediately. Our engineers will diagnose issues remotely. Critical failures trigger onsite repair within 48–72 hours.

What warranty do you provide?

1-year comprehensive warranty (parts/labor) and 2-year laser source warranty (extendable). Free lifetime technical support.

How is technical support handled?

24/7 multilingual support via WhatsApp, email, or live chat. On-site service available globally (fees apply for non-warranty issues).

How often do laser components need replacement?

Consumables like lenses/filters last 3–6 months under normal use. Spare parts are stocked globally for quick replacement.

Can I upgrade my machine’s software/features?

Yes. Software updates (e.g., cutting parameters, automation) are free during the warranty period. Hardware upgrades are chargeable.

What’s the difference between CO₂ and fiber lasers?

Fiber lasers are ideal for metals (faster, more efficient, lower maintenance). CO₂ lasers handle non-metals and thin metals but consume more power.

Are your machines compatible with CNC systems?

Yes, all models integrate with standard CNC controls for automated precision. We also offer custom integration services.

Do you provide technical documentation for machines?

Yes, including user manuals, maintenance guides, and video tutorials in multiple languages.

Logistics & Customization FAQs

Can you assist with local certifications/import regulations?

Yes. We provide compliance guides (CE, FDA, etc.) and collaborate with third-party agencies for regional certifications.

How are machines shipped?

Standard sea freight (containerized) or air freight (urgent orders). We handle customs documentation and coordinate with your logistics partner.

Do you provide localized training?

Free on-site training at your facility or ours. Customized training modules are available for bulk orders.

How often do laser components need replacement?

Consumables like lenses/filters last 3–6 months under normal use. Spare parts are stocked globally for quick replacement.

Can I upgrade my machine’s software/features?

Yes. Software updates (e.g., cutting parameters, automation) are free during the warranty period. Hardware upgrades are chargeable.

What’s the difference between CO₂ and fiber lasers?

Fiber lasers are ideal for metals (faster, more efficient, lower maintenance). CO₂ lasers handle non-metals and thin metals but consume more power.

Are your machines compatible with CNC systems?

Yes, all models integrate with standard CNC controls for automated precision. We also offer custom integration services.

Do you provide technical documentation for machines?

Yes, including user manuals, maintenance guides, and video tutorials in multiple languages.

General & Company FAQs

Do you have a global service center?

Yes. Some of our well-known partner brands have regional offices in Europe, North America and Asia to ensure local support. In addition to remote online technical support, we also provide technicians to travel on-site to help customers solve product technical problems.

Are you a manufacturer or trading company?

We’re a vertically integrated manufacturer with R&D, production, and global distribution capabilities.

Where is your company located?

Located in Shenzhen, China. Free factory tours and audits are available upon request.

How do I become an authorized distributor?

Submit a partnership proposal outlining your market reach, sales targets, and technical expertise. We prioritize long-term collaborations.

What is unique about your company?

Competitive pricing, full industry chain coverage, rapid prototyping capabilities, and commitment to sustainable development (energy-saving machines, environmentally friendly packaging).

What’s the difference between CO₂ and fiber lasers?

Fiber lasers are ideal for metals (faster, more efficient, lower maintenance). CO₂ lasers handle non-metals and thin metals but consume more power.

Are your machines compatible with CNC systems?

Yes, all models integrate with standard CNC controls for automated precision. We also offer custom integration services.

Do you provide technical documentation for machines?

Yes, including user manuals, maintenance guides, and video tutorials in multiple languages.