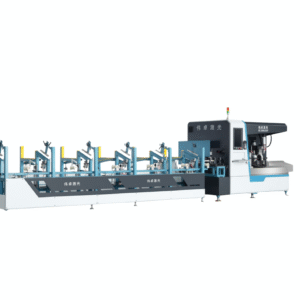

S Series 5-Axis Bevel Fiber Laser Tube Cutter | ±0.15mm Precision for Ø5-120mm Tubes

Engineered for complex applications, this machine delivers exceptional precision for bevels, chamfers, and intricate 3D profiles, enabling seamless splicing of finished parts. Featuring industry-leading ultra-short tailing technology (≤60mm) to minimize material waste and an extremely fast cutting speed, the S Series boosts productivity and ensures high-cost performance for your manufacturing operations.

The S Series S-S9Max/S12Max is a state-of-the-art 3D 5-axis fiber laser cutting machine designed to meet the most demanding tube and profile processing challenges. It integrates advanced bevel cutting capabilities with high-speed performance, providing a versatile and efficient solution for industries requiring complex cuts and superior edge quality. From stainless steel to aluminum, this machine handles a wide range of materials and tube shapes with unparalleled accuracy, eliminating the need for secondary processing and streamlining your entire production workflow.

✅ Advanced 3D 5-Axis Bevel Cutting:

The sophisticated 5-axis cutting head enables true bevel cutting, allowing you to create complex 3D profiles, chamfers for weld preparation, and intricate joints with a single operation. This drastically reduces production time and improves the quality of your finished products.

✅ Ultra-Short Tailing (≤60mm):

Maximize your material utilization and minimize waste with our innovative ultra-short tailing design. This feature significantly reduces the length of the unusable pipe end, directly translating to lower material costs and a higher return on investment.

✅ Extremely Fast Cutting Speed:

Engineered for high throughput, the S Series combines a powerful fiber laser source (1000W-6000W) with a dynamic motion system to deliver extremely fast and efficient cutting, significantly increasing your production capacity.

✅ High-Precision for Seamless Splicing:

With a processing precision of ±0.15mm, the machine produces parts with exceptional accuracy and consistency. This guarantees that components fit together perfectly for seamless splicing and assembly, ensuring the structural integrity and aesthetic quality of the final product.

✅ Versatile Tube & Material Processing:

Effortlessly cut a variety of profiles, including round, square, rectangular, and waist-shaped tubes. The machine is optimized for processing materials such as Stainless Steel, Carbon Steel, Aluminum, Copper, and Iron, making it a truly versatile asset for any workshop.

✅ High Cost Performance:

By combining high speed, minimal material waste, multi-functionality (cutting, beveling, profiling), and robust construction, the S Series offers an outstanding cost-performance ratio, delivering rapid ROI and long-term value.

◆ 60% Faster Setup: Automatic tube rotation and laser calibration.

◆ Zero Secondary Processing: Burr-free edges with N₂/O₂ assist gases.

◆ Energy-Smart Operation: 30% lower power consumption vs. CO₂ systems.

| Model | S-S9Max/S12Max | |

| Laser Power | 1000-6000W(Optional) | |

| Processing Precision | ±0.15mm | |

| Tailing length | ≤60mm | |

| Cutting Diameter of Round Tube | Φ5~120mm | |

| Cutting Diameter of Square Tube | 5*5mm~120*120mm | |

| Maximum length of machined pipe | ≤6500mm | |

| Cutting Material | Stainless Steel,Carbon Steel,Aluminum,Copper,Iron | |

| Cutting Tube Type | Round Tube,Square Tube,Rectangular Tube,Waist-Shaped Tube | |

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 13316792275

Bellona@shiguanglaser.com

+86 13430982872

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.