Effortless Operation, Material-Saving Precision for 3C, Automotive & Medical Industries

Simplify Your Production: The Easy-to-Operate CNC Laser Pipe Cutter for High-Speed, Zero-Learning-Curve Manufacturing.

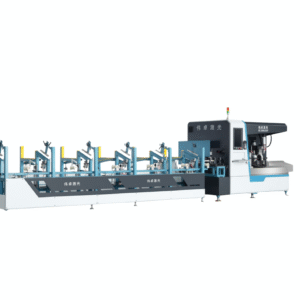

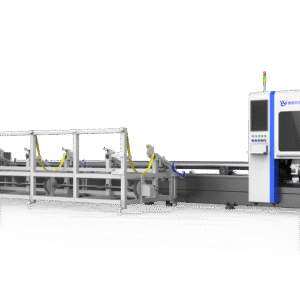

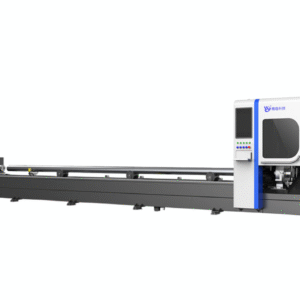

Shiguang Laser’s G100H 3D fiber laser tube cutter redefines metal processing efficiency with its no-drawing intelligent system and industry-leading components. Engineered for small-batch to mass production, this machine eliminates manual programming, minimizes material waste, and ensures stable precision—making it the ideal solution for businesses seeking to reduce labor costs and boost throughput. Backed by premium parts from Raycus/Maxphotonics and Hanli, it delivers consistent performance across diverse metal tube cutting needs.

The G100H redefines efficiency in tube fabrication. As a specialized high-speed 3D laser tube cutting machine , its revolutionary “Drawing-Free” operating system eliminates the need for complex CAD programming. Operators can select from dozens of pre-set cutting graphics—from simple holes to complex saddle cuts—directly on the intuitive Fangling control interface. This “zero-learning-curve” approach saves critical time, reduces labor costs, and simplifies operation. Combined with a design that minimizes tailing material, the G100H is the ultimate solution for workshops seeking maximum productivity and material savings.

Технические характеристики | Значение |

Модель | G100H |

Мощность лазера | 1500-3000W (Raycus/Maxphotonics/Create) |

Cutting Tube Range | Φ10-120mm (round), □10-100mm (square) |

Servo Repositioning Accuracy | ±0.05mm |

Max Tube Length | ≥6000mm |

Machine Dimension | 6800×800×1500mm |

Cooling Method | Dual-temperature water cooling |

Power Requirement | 220V/50Hz (±5% stability) |

The G100H’s versatility and ease of use make it ideal for high-volume, repetitive cutting tasks in various industries. The pre-built graphics library is perfectly suited for common joints and patterns.

Категории продуктов

Популярные товары

Сопутствующие товары

Ресурс

Телефон / Wechat

+86 13316792275

Электронная почта

Bellona@shiguanglaser.com

+86 13430982872

Адрес

3-й этаж, здание A, промышленный парк Runchang, район Longgang, город Шэньчжэнь, провинция Гуандун, Китай

Компания

Связаться с

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3-й этаж, здание A, промышленный парк Runchang, район Longgang, город Шэньчжэнь, провинция Гуандун, Китай

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. Все права защищены.