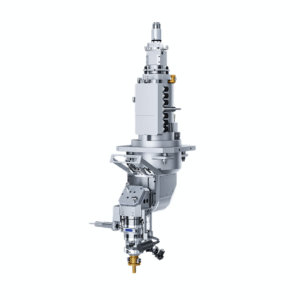

Streamline your weld preparation process with the OSPRI LCF Series, an intelligent bevel cutting head compatible with lasers up to 20kW. This head is designed to create precise bevels on flat sheet metal in a single, efficient operation. Featuring exceptionally fast autofocus (400mm/s), a robust anti-collision design, and a full suite of internal sensors with Bluetooth and optional 5G connectivity, the LCF Series eliminates secondary grinding and boosts productivity for advanced fabrication.

The OSPRI LCF Series brings the benefits of intelligent, high-power laser cutting to the world of beveling. By enabling the creation of precise, clean bevels for weld preparation directly on the cutting machine, it renders secondary grinding and milling operations obsolete. This saves immense time, labor, and workshop space, while also producing a more accurate and consistent result.

Compatible with lasers up to 20kW, the LCF is packed with OSPRI’s signature intelligence. It features internal gas pressure monitoring, Bluetooth connectivity for real-time monitoring, and an optional 5G module for remote data transmission. An independent protective window, internal water-cooling circuits, and a rugged anti-collision design ensure the head can withstand the rigors of continuous industrial use, delivering maximum uptime and performance.

✅ High-Speed Beveling:

Designed specifically for creating accurate bevels on plate metal, eliminating the need for time-consuming secondary operations.

✅ Lightning-Fast Autofocus:

With a focusing speed of 400mm/s and a wide focusing range, it maintains perfect focus while performing complex multi-axis movements.

✅ Advanced Connectivity & Monitoring:

Like other OSPRI heads, it features built-in sensors, Bluetooth monitoring, and optional 5G for complete process insight and Industry 4.0 integration.

✅ Robust Anti-Collision Design:

A dedicated anti-collision structure protects the head from damage due to programming errors or tipped parts, ensuring rapid recovery and minimal downtime.

✅ Superior Cooling:

Features sensor-monitored, internal water circulation cooling of the cavity to effectively manage heat and ensure optical stability during high-power operation.

✅ Process Optimization:

Compatible with advanced system features like process monitoring and a gas closed-loop to achieve the highest level of cut quality and efficiency.

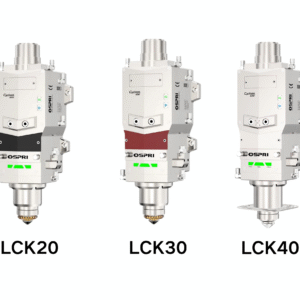

| Product model | LCF15A1 | LCF20A1 |

| Applicable power | 15kW | 20kW |

| Applicable wavelength | 1080nm±10nm | 1080nm±10nm |

| Collimation Length | 100mm | 100mm |

| Focal length | 250mm/300mm | 250mm/300mm |

| Focusing speed | 400mm/s | 400mm/s |

| Focusing range | -50mm~+50mm -70mm~+70mm | -50mm~+50mm -70mm~+70mm |

| Centering range | ±1.5mm | ±1.5mm |

| Gas Pressure | ≤3Mpa | ≤3Mpa |

| Overall weight | 9.5KG | 10KG |

| Interface type | Q+、QD、LOE3.1、LOE3.2 | Q+、QD、LOE3.1、LOE3.2 |

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.