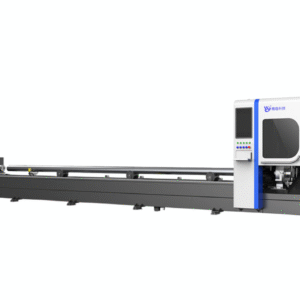

Engineered for the most delicate tasks, the CFZ-K utilizes an advanced Picosecond ultrafast laser. This technology performs “cold ablation,” vaporizing material with virtually no heat transfer to the surrounding area. This allows for flawlessly smooth, chip-free cutting of transparent and ultra-hard materials like glass, sapphire, and diamond, which are impossible to process cleanly with conventional lasers.

The CFZ-K Series, meticulously engineered for the most precise tasks, harnesses the cutting-edge power of an advanced Picosecond ultrafast laser. This innovative technology performs remarkable “cold ablation,” efficiently vaporizing material without generating any significant heat transfer to adjacent areas. Consequently, it enables impeccable, smooth, and chip-free cutting of transparent and ultra-hard materials such as glass, sapphire, and even diamond – a feat that conventional lasers have struggled to achieve due to their inadequate processing capabilities.

✅ Key Technology: Picosecond Ultrafast Laser

✅ Best For: Glass, sapphire, diamond, sensitive polymers

✅ Core Feature: “Cold” cutting with zero thermal stress for perfect edge quality.

| Model | CFZ0305L | CFZ0604L | CFZ0606L | |

| Processing area (L*W) | 500mm*300mm | 600mm*400mm | 600mm*600mm | |

| X-axis travel | 305mm | 405mm | 605mm | |

| Y-axis travel | 505mm | 605mm | 605mm | |

| Z-axis travel | 50mm | 50mm | 50mm | |

| X/Y axis repeat positioning accuracy | ≤0.005mm | ≤0.01mm | ≤0.01mm | |

| Maximum compound speed | 30m/min | 30m/min | 30m/min | |

| Maximum acceleration | 1.0G | 1.0G | 1.0G | |

| Laser power | Picosecond 30-150W Optional | Picosecond 30-150W Optional | Picosecond 30-150W Optional | |

| Chuck load-bearing | ≤200KG | ≤200KG | ≤200KG | |

| Machine weight | 2500Kg | 2800Kg | 3000Kg | |

| Machine Dimensions | 1900mm*1450mm*1800mm | 1900mm*1450mm*1800mm | 2150mm*1900mm*1800mm | |

◆Medical Devices: Manufacturing of stents, surgical tools, implants, and diagnostic components.

◆Electronics (3C): Cutting phone frames, internal components, and semiconductor materials.

◆Aerospace & Defense: Prototyping and production of complex, lightweight components.

◆Automotive: Precision cutting of fuel injector nozzles, sensors, and interior parts.

◆Jewelry & Watchmaking: Intricate cutting of precious metals and watch components.

◆Scientific Research: Fabrication of custom lab equipment, microfluidics, and optical components.

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 13316792275

Bellona@shiguanglaser.com

+86 13430982872

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.