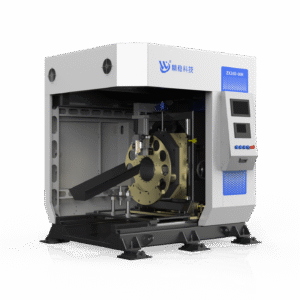

The CFZ-C is specially equipped with a Quasi-Continuous Wave (QCW) fiber laser, ideal for processing brittle and high-reflectivity materials like ceramics. The QCW laser provides high peak power with low thermal input, minimizing the heat-affected zone (HAZ) to prevent micro-cracking and ensure a perfect, clean-cut edge on materials like alumina and zirconia.

The LTGC CFZ-C Series are distinctively outfitted with a Quasi-Continuous Wave (QCW) fiber laser, rendering it perfectly suited for processing delicate and high-reflectivity materials such as ceramics. The QCW laser delivers robust peak power while maintaining minimal thermal input, effectively reducing the heat-affected zone (HAZ). This innovative feature mitigates the risk of micro-cracking and ensures the attainment of a flawless, clean-cut edge on materials like alumina and zirconia, thereby enhancing the overall quality and precision of the processing outcomes.

✅ Key Technology:

Quasi-Continuous Wave (QCW) Fiber Laser

✅ Best For:

Alumina ceramics, Zirconia ceramics, silicon wafers

✅ Core Feature:

Minimal heat damage for clean, crack-free cutting of brittle materials.

| Model | CFZ0305C | CFZ0604C | CFZ0606C | |

| Processing area (L*W) | 500mm*300mm | 600mm*400mm | 600mm*600mm | |

| X-axis travel | 305mm | 405mm | 605mm | |

| Y-axis travel | 505mm | 605mm | 605mm | |

| Z-axis travel | 50mm | 50mm | 50mm | |

| X/Y axis repeat positioning accuracy | ≤0.01mm | ≤0.015mm | ≤0.02mm | |

| Maximum compound speed | 30m/min | 30m/min | 30m/min | |

| Maximum acceleration | 1.0G | 1.0G | 1.0G | |

| Laser power | QCW150-600w Optional | QCW150-600w Optional | QCW150-600w Optional | |

| Chuck load-bearing | ≤200KG | ≤200KG | ≤200KG | |

| Machine weight | 2500Kg | 2800Kg | 3000Kg | |

| Machine Dimensions | 1900mm*1450mm*1800mm | 1900mm*1450mm*1800mm | 2150mm*1900mm*1800mm | |

◆Medical Devices: Manufacturing of stents, surgical tools, implants, and diagnostic components.

◆Electronics (3C): Cutting phone frames, internal components, and semiconductor materials.

◆Aerospace & Defense: Prototyping and production of complex, lightweight components.

◆Automotive: Precision cutting of fuel injector nozzles, sensors, and interior parts.

◆Jewelry & Watchmaking: Intricate cutting of precious metals and watch components.

◆Scientific Research: Fabrication of custom lab equipment, microfluidics, and optical components.

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 13316792275

Bellona@shiguanglaser.com

+86 13430982872

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.