LHQ Series All-in-One Laser Tube Welder & Cutter | Φ9.5–630mm | 50m/min | 0.2–12.7mm Thickness

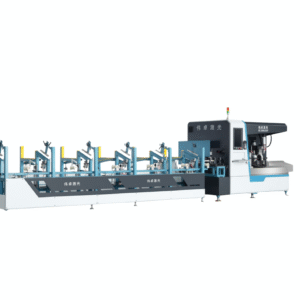

Streamline your entire tube manufacturing process with the JINGWEN LHQ Series, a fully integrated production line that takes flat metal coil and transforms it into precision-cut finished tubes. This all-in-one system combines high-precision forming molds, high-speed online laser welding, and automated online laser cutting. Capable of producing tubes up to Φ630mm at speeds up to 50m/min, the LHQ Series is the ultimate solution for high-volume, high-quality tube manufacturing with exceptional cost-performance.

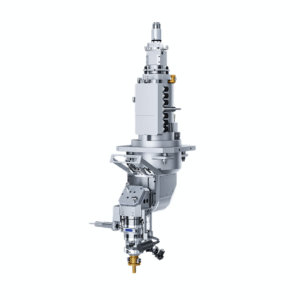

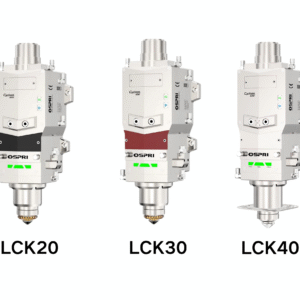

The JINGWEN LHQ Series is a complete, end-to-end laser tube mill designed to replace traditional, multi-step production methods. This sophisticated system automates the entire workflow: it uncoils raw material, forms it into a precise profile using high-quality molds, performs a flawless straight-seam weld using a high-power fiber laser, and cuts the continuous tube to the desired length with an integrated online laser cutter.

By replacing older technologies like high-frequency induction or TIG welding, the LHQ Series offers superior weld quality with a smaller heat-affected zone, resulting in a stronger, smoother, and more aesthetically pleasing seam. With minimal consumables and a highly efficient process, this production line delivers unparalleled productivity and a rapid return on investment for any large-scale tube manufacturer.

✅ Fully Integrated Production:

Combines forming, online laser welding, and online laser cutting into a single, continuous, and automated process, drastically reducing labor and handling time.

✅ High-Speed, High-Volume Output:

With processing speeds ranging from 0.2m to 50m per minute, the LHQ Series is engineered for maximum throughput to meet the most demanding production schedules.

✅ Superior Weld Quality:

Fiber laser welding produces a clean, deep-penetration weld with minimal spatter and a narrow seam, often eliminating the need for post-weld scarfing or grinding.

✅ Exceptional Versatility:

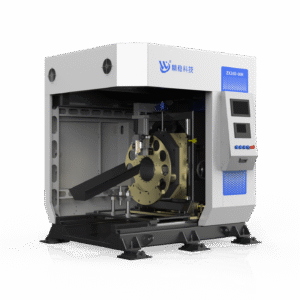

Capable of processing a wide range of materials and profiles, including round, square, rectangular, and custom shapes with diameters from Φ9.5mm up to a massive Φ630mm.

✅ Low Consumables & High Cost-Performance:

The laser process requires no filler rods or welding electrodes, and the high efficiency of the system minimizes energy consumption and waste, leading to a significantly lower cost per meter.

✅ Precision Forming Molds:

Utilizes high-precision welded pipe molds to ensure consistent tube dimensions and shape accuracy throughout the entire production run.

| LHQ Series High-speed&Stable Fiber Laser Pipe Welding Unit with High Precision Welded Pipe Molds | ||

| Model | LHQ-H40/H50/H60/H70/H80/H90/H100/H120 | |

| Processing Precision | 0.2mm~12.7mm | |

| Processing Speed | 0.2m~50m | |

| Cutting Diameter of Round Tube | Φ9.5~Φ630mm | |

| Cutting Material | Stainless Steel,Carbon Steel,Aluminum,Copper,Iron | |

| Cutting Tube Type | Round Tube,Square Tube,Rectangular Tube,Waist-Shaped Tube | |

The LHQ Series is the definitive choice for industries that require in-house, high-volume manufacturing of welded tubes:

◆ Structural Steel & Construction

◆ Automotive Frames & Components

◆ Furniture Manufacturing

◆ Oil, Gas, and Water Pipeline Production

◆ Agricultural Machinery

◆ General Metal Fabrication

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.