In the context of laser processing equipment procurement, understanding how lasers are generated is more than just academic. A clear grasp of different laser types—such as fiber, disc, YAG, and semiconductor lasers—can directly influence equipment selection, cost estimation, and application suitability. This article outlines the fundamental theory behind laser generation, the structural design of laser sources, and a classification of common industrial laser types.

What Is a Laser and How Is It Generated?

The term “laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. The concept stems from Einstein’s early 20th-century theory of stimulated emission, and the modern Chinese translation, “激光” (jiguang), was proposed by renowned scientist Qian Xuesen.

At its core, laser generation involves the amplification of light via stimulated emission. This process requires an understanding of quantum energy levels, electron transitions, and interactions between photons and atomic particles.

Theoretical Foundations

1. The Bohr Model

Atoms consist of a nucleus and orbiting electrons. These electrons occupy discrete energy levels. The lowest level is known as the ground state, and higher levels are called excited states. When electrons absorb energy, they move from the ground state to an excited state. Upon returning to a lower state, they release energy, often in the form of photons—this is the basic mechanism behind light emission.

2. Einstein’s Theory of Stimulated Emission

Einstein defined three types of interactions between photons and electrons:

- Spontaneous Emission: An excited electron randomly returns to a lower energy state, emitting an incoherent photon.

- Stimulated Absorption: An electron in a lower energy state absorbs a photon and transitions to a higher state.

- Stimulated Emission: An incoming photon causes an excited electron to drop to a lower energy state, releasing a second photon that is identical in phase, frequency, and direction.

Stimulated emission is the critical process for producing coherent laser light. When this process occurs repeatedly within a population of excited particles, laser action is achieved.

Conditions for Laser Generation

To sustain stimulated emission and produce laser output, three components are necessary:

- Gain Medium: A material that provides amplifiable photons (e.g., Nd:YAG crystal, doped fiber, CO2 gas).

- Pump Source: Provides external energy (optical or electrical) to excite electrons to higher energy levels, creating a population inversion.

- Optical Resonator: Typically composed of two mirrors, it forms a cavity that allows photons to bounce back and forth, reinforcing stimulated emissions.

These elements together form the fundamental architecture of a laser.

Common Industrial Laser Types

● CO2 Lasers

- Gain Medium: CO2 and He gas mixture

- 파장: 10.6 μm

- 애플리케이션: Non-metal cutting (textiles, plastics, wood), photolithography

- Characteristics: Space beam delivery (not fiber-transmissible), mature technology

● Nd:YAG Lasers

- Gain Medium: YAG crystal doped with Nd or Yb ions

- 파장: 1.06 μm

- 애플리케이션: Metal welding, pulse applications, early 3C electronics manufacturing

- Characteristics: High peak power, typically pulsed, fiber-compatible

● Fiber Lasers

- Gain Medium: Ytterbium-doped fiber

- 파장: 1060 nm

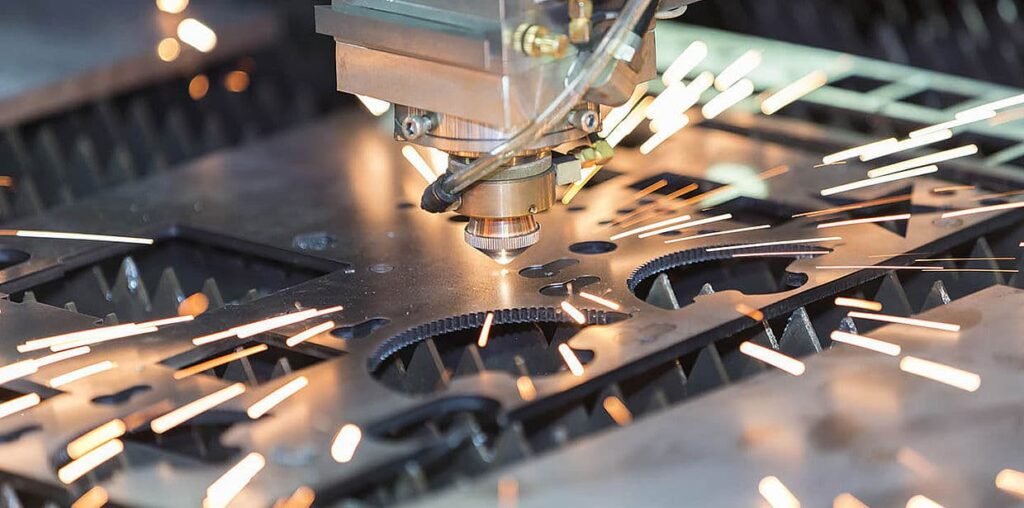

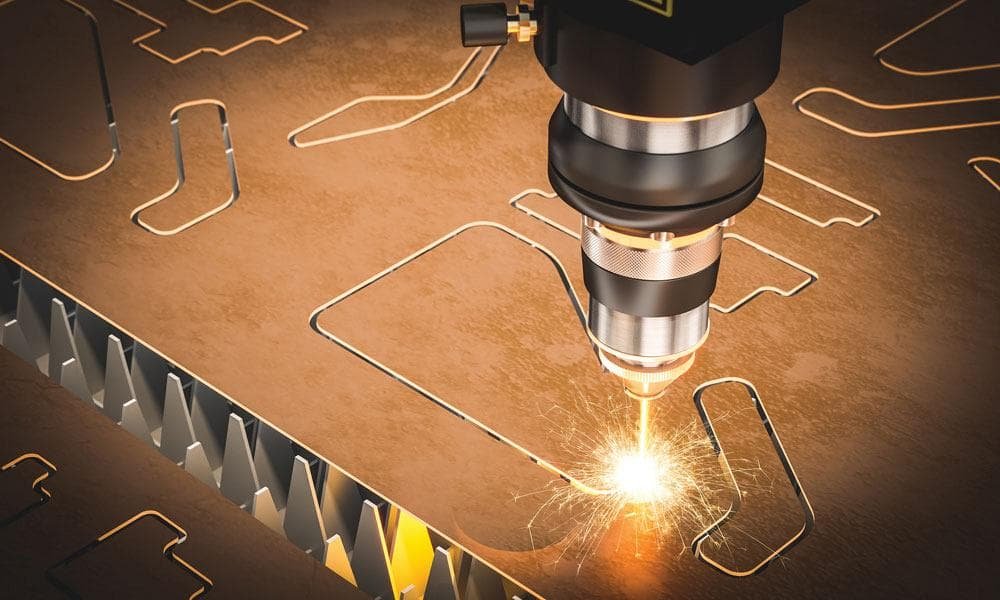

- 애플리케이션: Metal cutting, welding, engraving, marking

- Characteristics: Market mainstream, excellent beam quality, high reliability

● Disc Lasers

- Gain Medium: Thin disc-shaped gain medium

- Representatives: TRUMPF

- Characteristics: High-power, good beam quality, efficient cooling

● Semiconductor Lasers

- Gain Medium: Semiconductor PN junction

- 파장: ~976 nm

- 애플리케이션: Cladding, high-power near-infrared uses

- Representatives: Laserline

Laser Modes by Energy Output Format

● Pulsed Lasers (ns/ps/fs)

- Features: High peak power, minimal thermal distortion

- 애플리케이션: Microfabrication, cleaning, ultra-thin materials (e.g., <0.5mm)

● Quasi-Continuous Wave (QCW)

- Features: Peak power up to 10x average power; pulse width 50μs–50ms

- 애플리케이션: Precision welding, intermediate applications between CW and pulsed

● Continuous Wave (CW)

- Features: Stable, long-duration output

- 애플리케이션: General-purpose cutting, welding; widely used in fiber laser systems

Conclusion

For decision-makers in laser equipment procurement, understanding the fundamentals of laser generation and the distinctions among different laser types is crucial. From system integration to long-term process reliability, the choice of laser source impacts not just initial performance but also ongoing operational cost and scalability. Whether you’re considering a high-power fiber laser for thick metal cutting or a precision pulsed system for micro-processing, knowing what goes on inside the laser can help you make smarter, more informed investments.