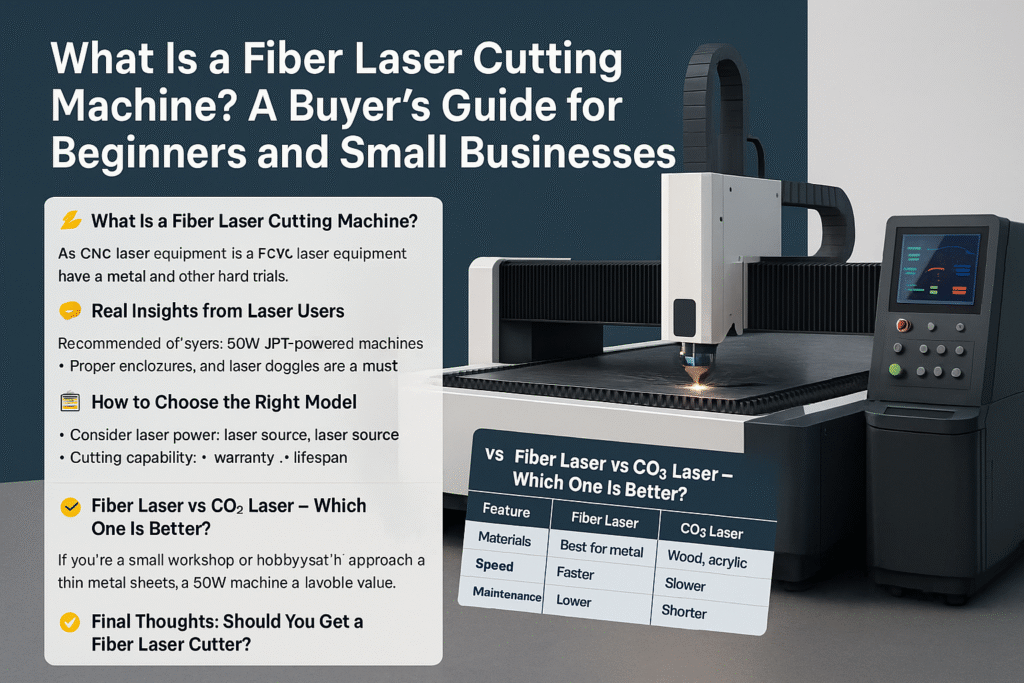

Fiber laser cutting machines are becoming an essential tool for small businesses and makers looking to cut and engrave metal with precision. If you’re exploring your options and wondering whether fiber laser technology is right for you, this guide will walk you through the essentials—from how these machines work to choosing the best model for your workshop.

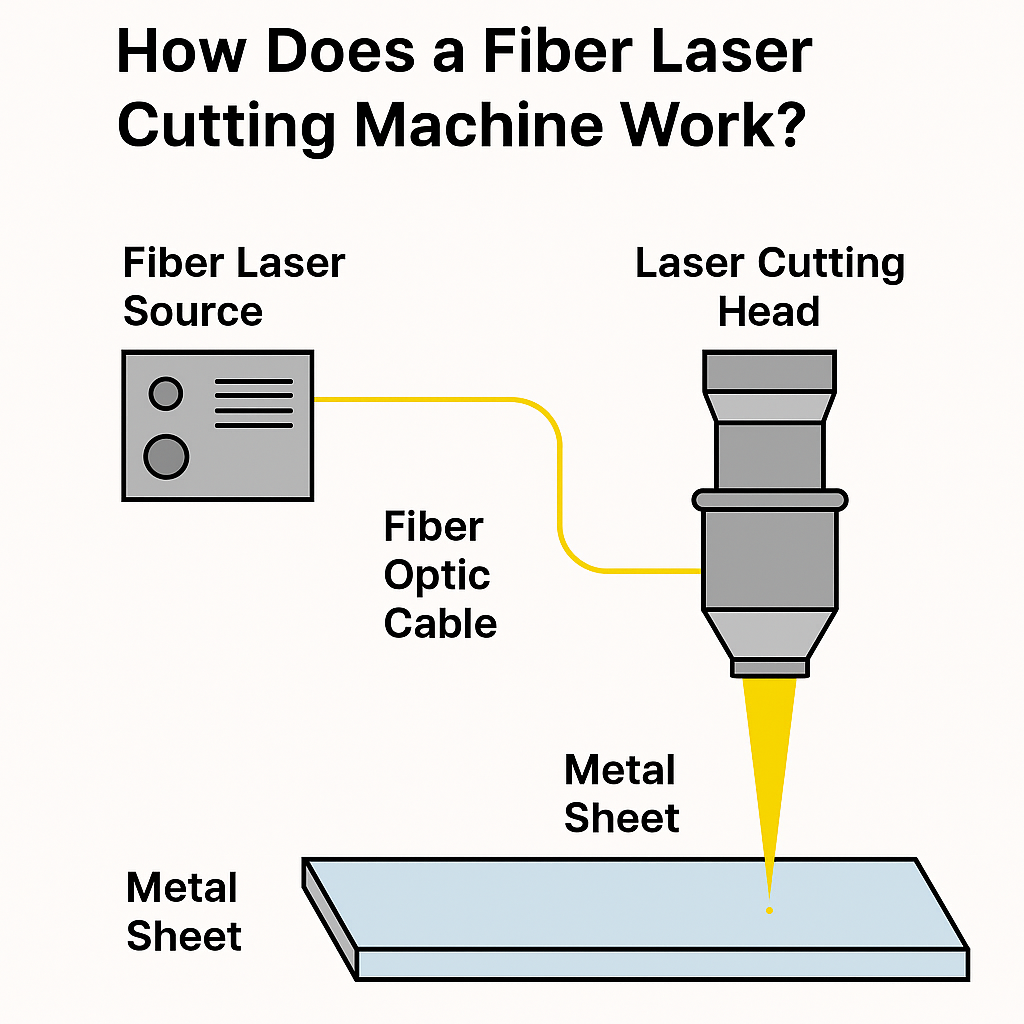

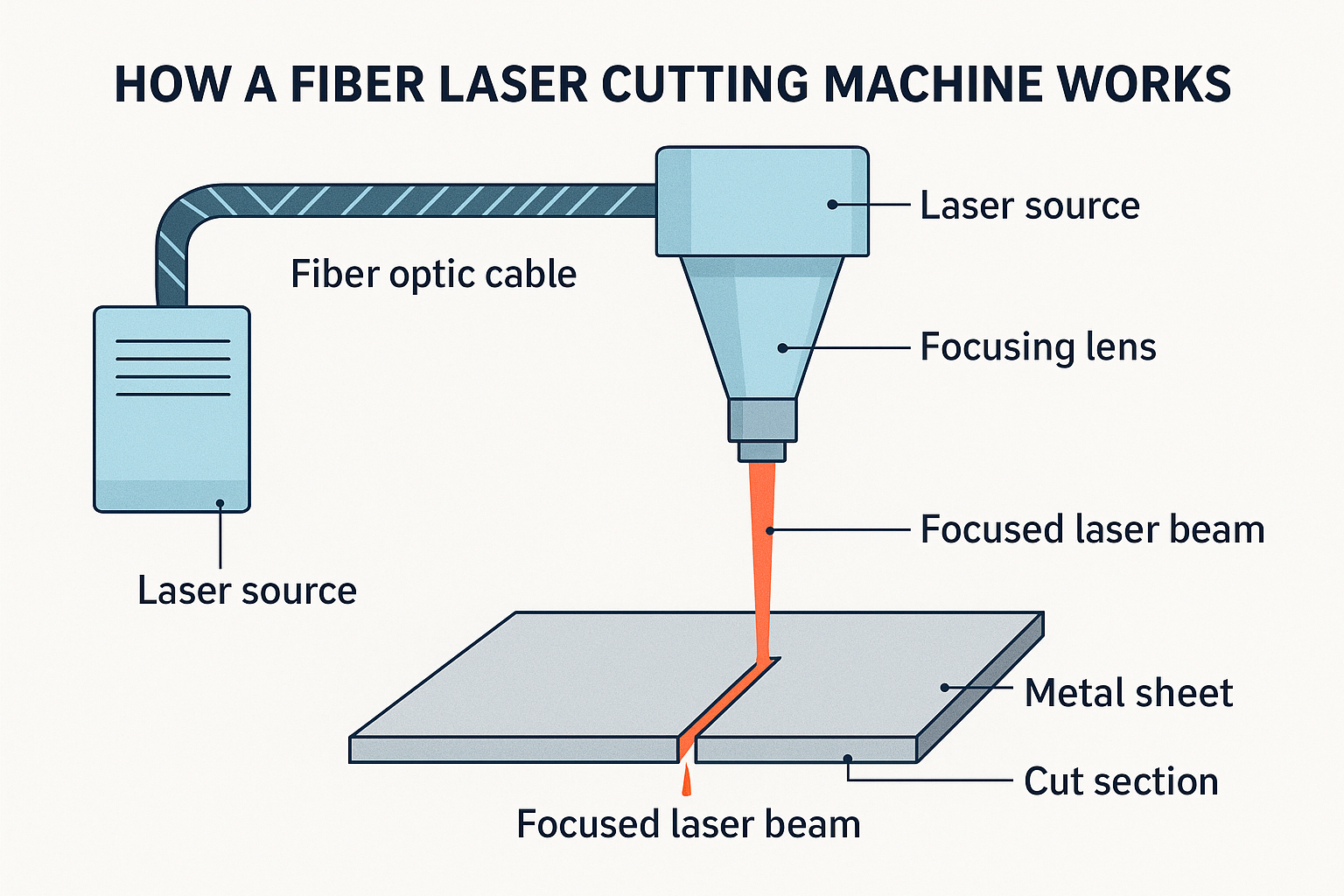

How Does a Fiber Laser Cutting Machine Work?

A fiber laser uses a high-powered laser beam transmitted through fiber optic cable to cut or etch metal. Unlike traditional CO₂ lasers, fiber lasers operate at a shorter wavelength (~1064 nm), making them more effective for reflective materials like stainless steel and aluminum. They’re ideal for:

- Stainless steel

- Carbon steel

- Aluminum

- Copper

- Titanium

What Users Are Saying

On forums like Reddit, small shop owners often recommend 50W JPT-powered machines as a good entry point. One user reported paying under $7,000 for a setup with rotary attachments and multiple lenses, and saw great performance for engraving and light cutting.

Most users agree that while fiber lasers aren’t suitable for wood or plastic, they are unmatched when it comes to cutting metal cleanly and efficiently.

How to Choose the Right Fiber Laser Cutter

Here are a few things to consider before buying:

1. Power Output

50W is typically sufficient for light-duty metal cutting and engraving (up to 2 mm). For thicker materials or industrial use, look for 100W or higher.

2. Laser Source

Brands like JPT, Raycusund IPG are known for stability, longevity, and reliable performance.

3. Features

- Rotary axis for cylindrical parts

- Swappable lenses for different materials

- Auto-focus and software integration

4. Warranty & Support

Choose a brand with U.S.-based support or international technician networks. A 1–2 year warranty is standard.

Fiber vs. CO₂ Lasers

| Feature | Faserlaser | CO₂ Laser |

|---|---|---|

| Material Focus | Metals | Non-metals |

| Speed | Faster on metal | Slower on metal |

| Maintenance | Lower | Higher |

How Much Do Fiber Laser Cutting Machines Cost?

Entry-level machines (30W–50W) from brands like OMTech or BossLaser typically range from $5,000–$8,000. Industrial-grade models with 100W+ can go beyond $20,000 depending on features.

Look for systems that include:

- Reliable laser source (JPT/Raycus/IPG)

- Rotary tools

- Safety enclosure

- Onsite/remote support options

Final Thoughts

If you’re a small manufacturer or a creator working with metals, a fiber laser cutting machine can be a transformative investment. With more affordable options and better support, it’s easier than ever to get started.

Need help choosing the right machine? Contact Shiguang Laser and get expert support tailored to your needs.