Walk into any modern fabrication shop today—whether it’s working on aluminum sheet repairs, building marine parts, or restoring car frames—and chances are, someone’s using a fiber laser welding machine. These compact but powerful tools are quickly becoming the go-to option for precise, low-distortion welds on both standard and hard-to-join materials like aluminum or stainless steel.

And no, it’s not just about the “cool tech” factor—this shift is backed by real-world results and enthusiastic feedback from experienced Reddit users, especially those who’ve moved away from TIG/MIG setups for certain jobs.

🔍 How Fiber Laser Welding Machines Actually Work

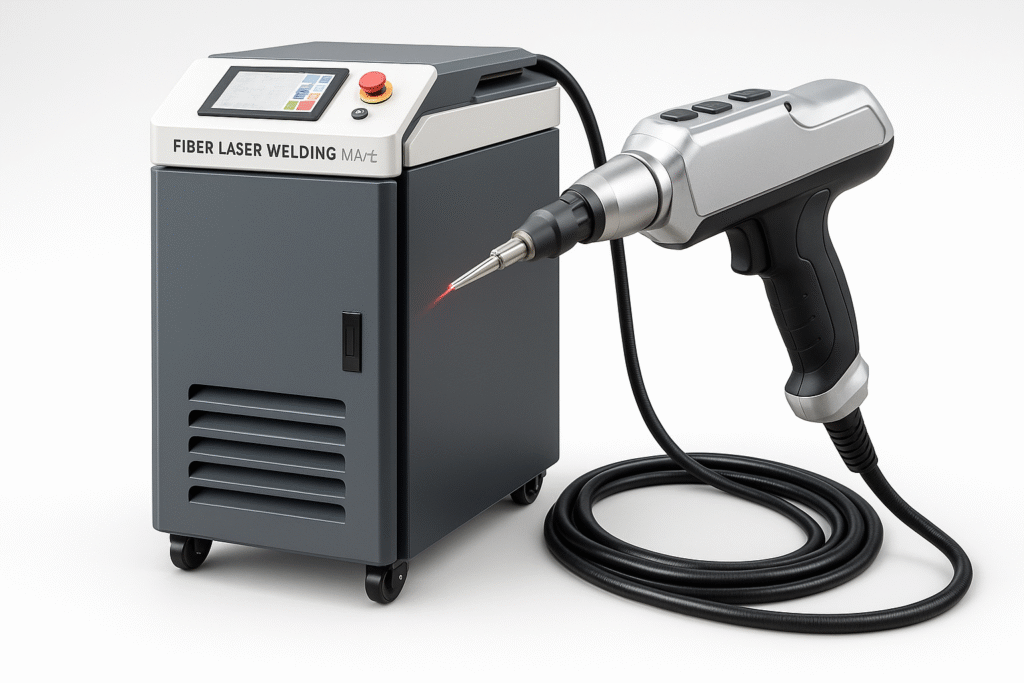

The basic idea is simple but effective: a high-energy laser beam (usually powered by a ytterbium-doped fiber source) is focused and delivered through an optical cable into a handheld gun. At the tip, the beam heats the base metal so precisely that it melts and fuses materials cleanly, even on thin or reflective surfaces.

🛠️ Core Components Breakdown:

- Fiber laser module: High beam quality and low maintenance

- Delivery cable: Carries beam to the handheld welding head

- Optics system: Concentrates the laser precisely on the weld seam

- Cooling system: Often water-cooled for longer-duty cycles

- Handheld gun: Easy to maneuver for different joint angles

- Control interface: Adjusts pulse mode, power, and travel speed

👨🔧 Reddit DIYers & Welders Share: “Why I Switched”

“The penetration depth was solid, even at 3mm thickness. I used to struggle with TIG on this stuff, but this was much faster and less cleanup.”

Another noted that laser welding let them bridge gaps between dissimilar metals like 5052 aluminum and stainless brackets—something they would’ve avoided with traditional arc welders due to warping.

✅ Pros and Cons of Fiber Laser Welding Machines

Advantages

- ⚡ Fast: Welding speeds are often 2–10× quicker on thin sheet metals

- 🎯 Precise: Less post-grind work due to minimal spatter

- 🔄 Versatile: Can weld steel, aluminum, brass—even dissimilar combinations

- 🧳 Portable: Ideal for onsite maintenance or field service jobs

- ♻️ Cleaner joints: No filler wire needed in many cases

Limitations

- 🔍 Requires exact alignment; poor prep = poor results

- 💡 Reflective metals (like aluminum) need correct beam tuning

- 💰 Initial cost is higher than MIG/TIG machines

- 🧯 Safety setup mandatory: Laser goggles, shielding curtain, exhaust venting

🧪 Safety Protocols & Setup Checklist

Pre-Weld Setup

- Degrease and clean base metals

- Align parts with clamps

- Confirm shielding gas and cooling systems are active

During Weld

- Trial pulse test → check seam edge fusion

- Track puddle depth visually

- Use Class-4 rated goggles & wear protective gear

- Keep workspace enclosed and well-ventilated

🧱 Material Compatibility: What Can You Weld?

Handheld laser systems are particularly effective on:

- Aluminum (5052 works great; 6061 may crack—test first)

- Stainless & carbon steel

- Copper/brass

- Titanium (thin sections, with proper control)

Also capable of dissimilar joints like:

- Aluminum-to-steel

- Stainless-to-copper

🛒 Choosing the Right Machine: Practical Tips

- Power rating: 500W–1500W = good for up to 4mm Alu; >2000W = deeper welds

- Beam type: Continuous is standard; pulsed helps on thin stock

- Cooling: Water-cooled for longer jobs

- Controls: Look for presets for aluminum/stainless

- Brand matters: Avoid no-name imports with no warranty or training

- Dienst: Choose vendors that offer setup help and maintenance support

🚀 Conclusion: Is It Time to Switch?

For metalworkers and fabrication shops who value clean welds and faster workflow, fiber laser welding is more than hype—it’s a practical upgrade. From smoother seams on marine fittings to one-pass welds on 3mm aluminum, the efficiency gains are hard to ignore.

That said, don’t expect plug-and-play. Know your alloys, prep your materials, and treat safety seriously.

💬 Ready to Explore Options?

Contact Shiguang Laser for a personalized consultation, machine recommendation, or sample welding session.