Laser cutting equipment has emerged as one of the most promising sectors within China’s broader laser processing industry. It is a technology-intensive and innovation-driven field that spans multiple disciplines, including laser optics, electronics, computer software development, power systems, industrial control, and mechanical design and manufacturing. This article provides an in-depth analysis of China’s laser cutting equipment industry, covering upstream and downstream developments, market dynamics, technological trends, and future prospects.

Laser Cutting Equipment Industry Characteristics

Laser cutting equipment is not only capital- and technology-intensive but also heavily reliant on interdisciplinary knowledge. It integrates:

- Laser optics

- Electronic control systems

- CNC and motion control software

- Industrial power sources

- Precision mechanical engineering

China has become a major player in this global market, with its domestic capabilities rapidly expanding in recent years.

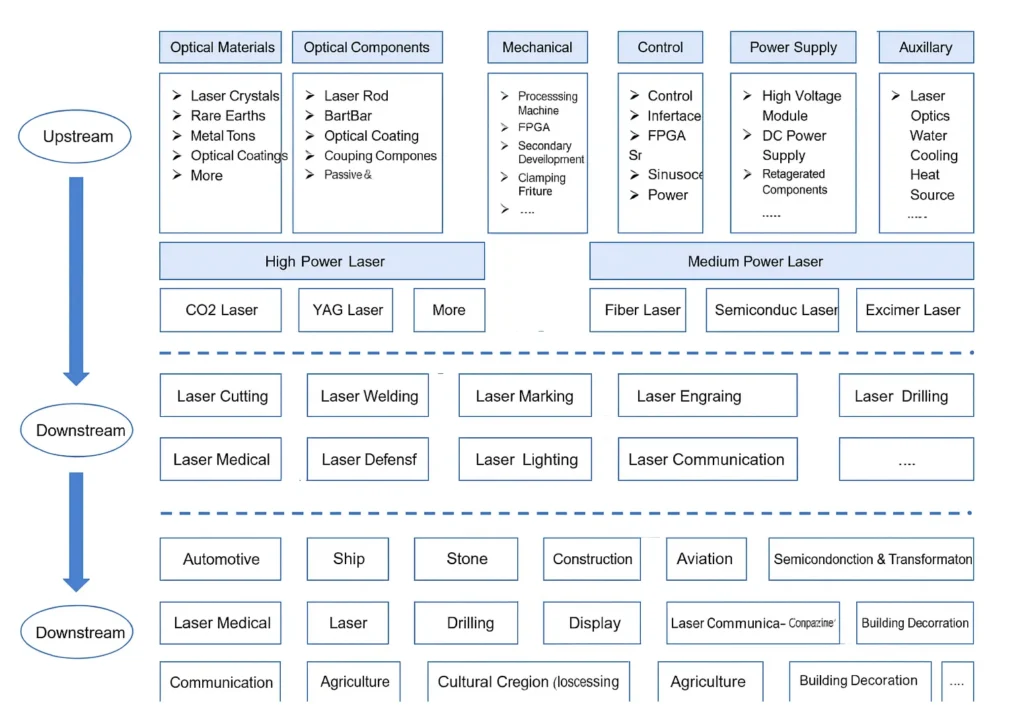

| Segment | Description |

|---|---|

| Upstream | Optical materials and components, laser heads, fiber lasers, motion control systems |

| Midstream | Equipment assembly: laser cutting, laser welding, laser marking systems |

| Downstream | Application industries: automotive, electronics, aviation, medical, smart manufacturing |

Upstream Industry Development

In the upstream segment, the optical component manufacturing sector in China has become increasingly concentrated. While the core technologies in optical component production were initially dominated by overseas suppliers, the past decade has seen China significantly improve its research and development capabilities. The localization rate of critical components for laser processing equipment continues to rise, effectively reducing procurement costs and driving down the manufacturing cost of laser cutting systems.

Take fiber lasers, for instance—currently the most dominant laser type used in cutting applications. Chinese fiber laser manufacturers have made considerable breakthroughs, allowing them to capture substantial market share from international competitors. As a result, fiber laser prices in the Chinese market have decreased, enabling domestic manufacturers to expand quickly into downstream sectors with cost-competitive solutions.

Example: Fiber Laser Price Trends and Localization

Chinese manufacturers have achieved breakthroughs in fiber laser technologies, enabling them to capture market share from overseas players. This has led to:

- Lower costs for fiber lasers

- Reduced system integration costs

- Faster adoption in downstream industries

Downstream Industry Trends

Laser cutting technology finds wide and diverse applications in China, spanning sectors such as 3C electronics, industrial manufacturing, rail transit, and aerospace. These downstream industries play a vital role in driving demand and shaping the development of the laser cutting equipment market.

Government policy has also played a key role. Numerous initiatives promoting industrial transformation and technological upgrades have provided fertile ground for innovation in downstream industries, in turn accelerating the expansion of laser cutting applications. The global rise of Industry 4.0 has further fueled the upgrading of China’s manufacturing sector, strengthening demand for intelligent, high-efficiency laser systems.

Laser Cutting Equipment Product Types

1. Flatbed Fiber Laser Cutting Machines

These systems use fiber lasers, auto-focus cutting heads, and intelligent control software to cut flat metal sheets with varying sizes and thicknesses.

Main Application Areas:

- Precision equipment

- Automotive parts

- Kitchen and bathroom hardware

- Electronics

- Smart appliances

2. Tube Fiber Laser Cutting Machines

Tube laser cutters use special motion control algorithms and optical systems to cut round, square, and custom-section pipes.

Main Application Areas:

- Agricultural machinery

- Industrial machinery

- Furniture

- Fitness equipment

Supported pipe types:

| Type | Description |

|---|---|

| Small tubes | Precision electronics |

| Medium tubes | Fitness equipment |

| Large tubes | Industrial machines |

| Extra-heavy tubes | Structural parts |

Overview of the Laser Cutting Equipment Market

As the global economy recovers and investment in manufacturing rebounds, China’s laser processing industry has entered a phase of rapid development. Laser technologies are increasingly replacing traditional manufacturing methods thanks to their high speed, precision, and quality.

Advantages of Laser Technology

Laser processing is widely favored due to its superior characteristics over traditional machining methods:

| Advantage | Description |

|---|---|

| High precision | Micron-level accuracy and minimal thermal distortion |

| Non-contact | No mechanical force on the material, reducing deformation |

| Material savings | Efficient use of material, saving 10–30% on average |

| High efficiency | Processes like cutting, welding, and drilling are dozens of times faster |

| Flexibility | Easily integrated into automated and digital production lines |

Laser Cutting vs. Traditional Processing

Compared to conventional methods, laser cutting is:

- Faster and more efficient

- More precise with less heat deformation

- Better suited for flexible and complex tasks

- Easier to automate and integrate into digital workflows

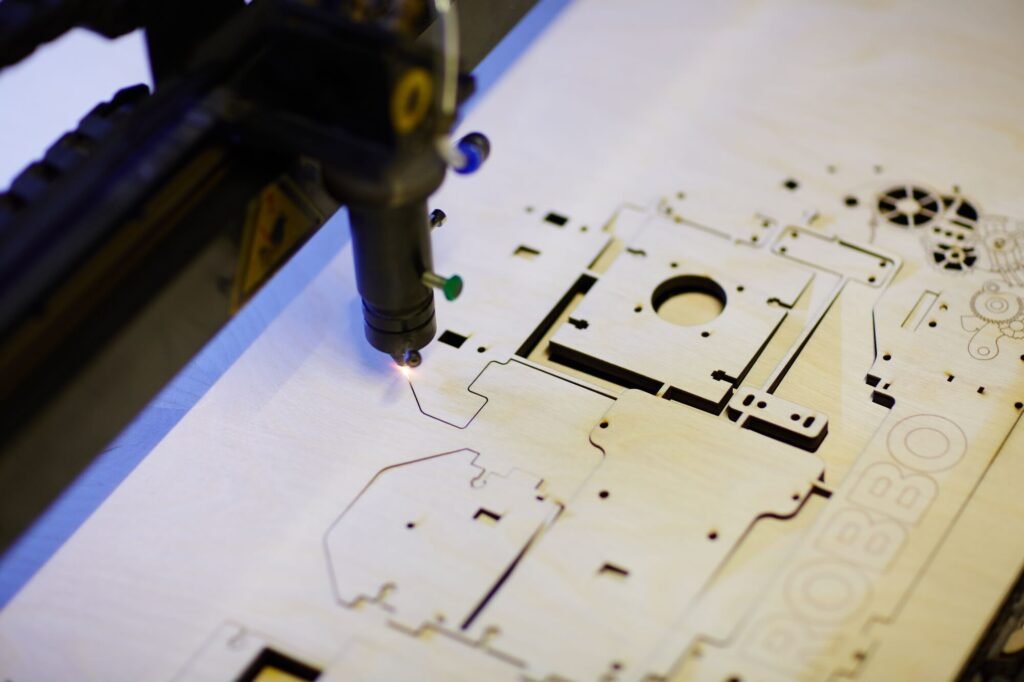

Key Laser Cutting Applications

Laser cutting equipment can process a variety of materials including metals, plastics, ceramics, glass, semiconductors, wood, and paper. In China, high-power laser cutting machines are widely used in heavy machinery and industrial parts, while precision cutting is increasingly used in electronics, smart home appliances, and EV manufacturing.

China’s Market Growth

According to the 2022 China Laser Industry Development Report, China’s laser cutting equipment market reached ¥28 billion (approx. $4.3 billion USD) in 2021, growing 6.6% year-on-year. Laser cutting accounted for 34% of the total laser equipment market, making it the largest single application segment.

As China’s economy recovers and manufacturing industries upgrade, laser cutting demand continues to rise. Between 2018 and 2020, its share of total laser applications grew from 35% to 41%, a trend expected to continue.

Surge in High-Power Laser Cutting Systems

China’s manufacturing boom and industrial modernization have driven rapid growth in equipment sales. While mid- and low-power systems have already reached high levels of domestic production, demand for high-power systems is accelerating.

According to the 2021 China Laser Industry Development Report, mid-power (<3kW) and high-power (≥3kW) system sales grew by 23.5% and 85.7% year-on-year, respectively.

Application Segments by Power Range

- <1,000W: Semiconductor and 3C electronics precision cutting

- 1,000–6,000W: Sheet metal in hardware, appliances, enclosures

- >6,000W: Aerospace, railway, oil pipeline, and heavy industry

Rapid Innovation in Downstream Applications

As China’s economy and industrial technology evolve, sectors such as precision instruments, automotive parts, kitchenware, electronics, and smart home devices continue to show strong demand. This rapid development has placed higher demands on processing quality and equipment adaptability.

Laser cutting equipment manufacturers must therefore pursue constant innovation—enhancing speed, precision, versatility, and automation to meet ever-changing market needs.

Future Directions and Opportunities

1. Higher Power, Higher Precision

With the emergence of 20kW+ fiber lasers, the industry is pushing the limits of cutting thickness and efficiency. High-power, high-speed systems will continue to replace traditional processing tools, offering superior throughput and performance.

2. Digitalization and Intelligence

Integrating CNC and AI, laser cutting machines are evolving into smart manufacturing units capable of self-analysis, optimization, and decision-making. Labor cost pressures and ongoing industrial upgrades in China are accelerating the adoption of automated, intelligent equipment.

3. Flexibility and Modularity

As user needs become more diverse and complex, laser systems must adapt to multi-scenario tasks. Modular design, higher integration, and flexible production capabilities will define the next-generation laser cutting equipment.

Conclusion

China’s laser cutting equipment industry is undergoing transformative growth. Supported by strong policy, accelerating downstream demand, and a robust supply chain, laser cutting has become the leading application within the laser sector. Looking ahead, high-power, intelligent, and flexible solutions will shape the future of this industry, positioning China as a global leader in advanced laser manufacturing.

About Shiguang Laser

Shiguang Laser is a leading manufacturer of laser cutting, welding, and laser component systems based in China. With a strong foundation in R&D and manufacturing, we offer high-performance fiber laser solutions designed for precision, efficiency, and scalability. Our product portfolio includes flatbed laser cutters, professional tube laser cutting machines, handheld laser welders, and customized systems for a wide range of industries—from automotive and aerospace to home appliances and industrial machinery.

We are committed to advancing smart manufacturing through reliable, cost-effective, and intelligently engineered laser technologies. Backed by years of technical expertise and deep market insight, Shiguang Laser continues to support our clients in achieving higher productivity and lower operational costs.

Let’s Cut Smarter — Together

Looking to upgrade your production line with high-efficiency laser equipment?

👉 Get in touch with Shiguang Laser for a free consultation, technical support, or customized solution tailored to your cutting needs.