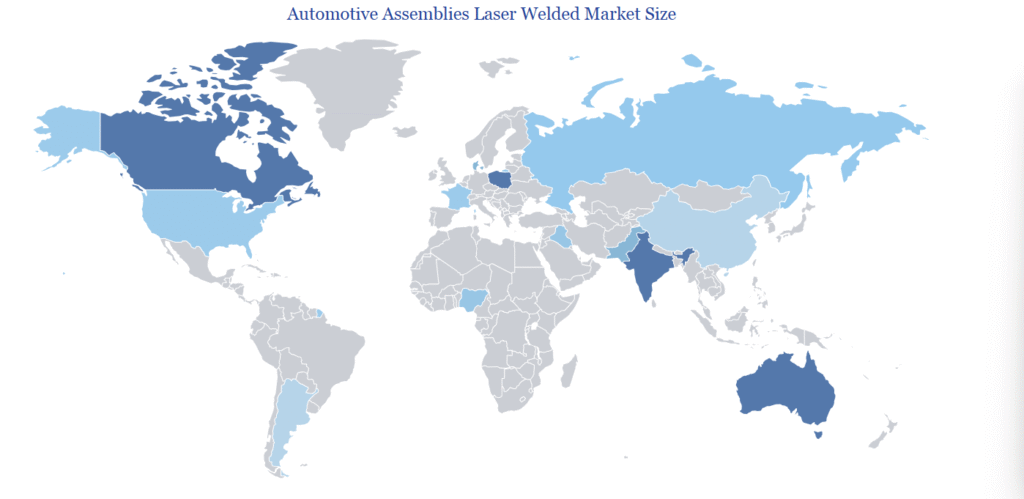

1. Market Overview: The Expanding Laser Welding Landscape

The global industrial laser welding market has reached $2.9 billion in 2025, with automotive applications accounting for 38% of this growth. Driven by the electrification revolution, laser welding adoption is accelerating at a 5.2% CAGR, with particularly strong growth in battery manufacturing segments where precision requirements are most stringent . This expansion reflects the technology’s transformative impact on production efficiency—enabling automakers to achieve 30% higher joint strength while reducing manufacturing time by up to 75% compared to traditional methods.

The competitive landscape is dominated by a mix of established players and emerging innovators. While Trumpf and IPG Photonics lead in high-power systems, Han’s Laser has captured 41% of China’s power battery welding equipment market, demonstrating the globalization of laser welding technology.

2. Core Technologies: Global Innovations in Laser Systems

Modern automotive laser welding relies on three technological pillars: high-power laser sources, precision delivery systems, and advanced process monitoring. International manufacturers have pushed boundaries with:

- High-Power Fiber Lasers: IPG Photonics’ 30kW systems achieve penetration depths up to 25mm in steel while maintaining beam quality (M² < 1.5) critical for automotive applications

- Remote Laser Welding (RLW): Trumpf’s TruDisk lasers combined with SCANLAB galvanometer scanners reduce cycle times by 80% through 3m/s beam movement speeds

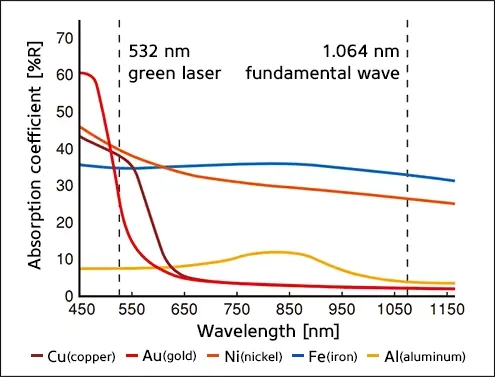

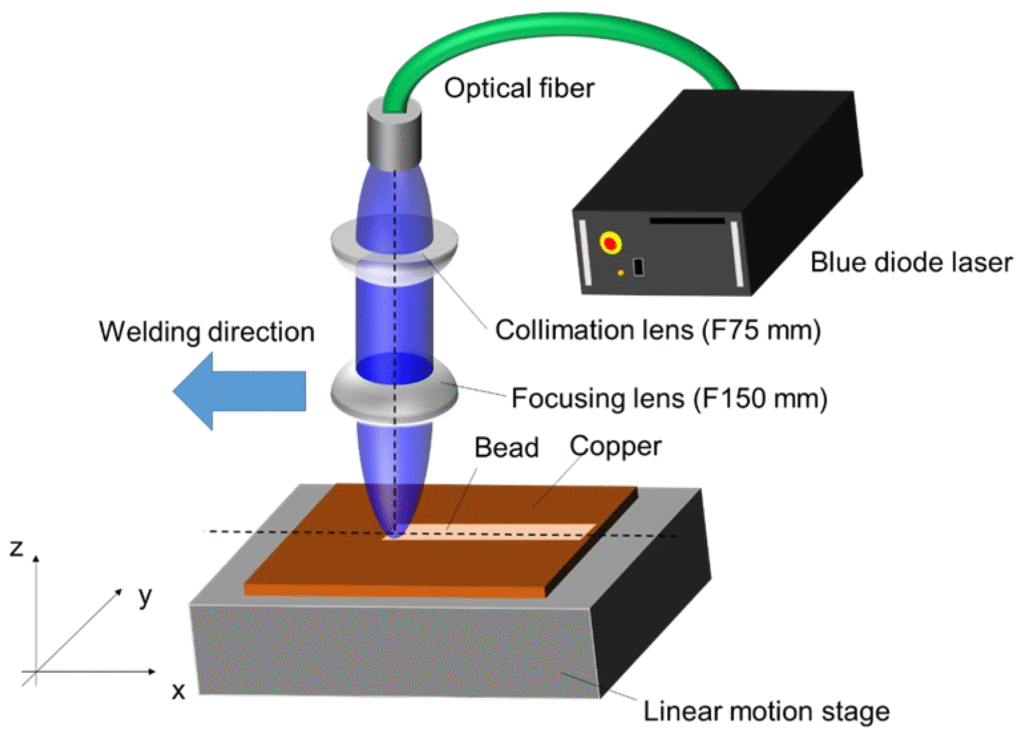

- Wavelength Diversity: Green (532nm) and blue (450nm) lasers now address high-reflectivity materials, with copper absorption rates improved from 5% (IR lasers) to 50% with green variants

Key innovations include adaptive beam oscillation technology, where programmable wobble patterns (100-1000Hz) expand process windows for imperfect joint fits—a critical advancement for high-volume automotive production . Real-time monitoring systems now analyze 200+ parameters simultaneously, adjusting laser power and speed in milliseconds to maintain consistent weld quality.

3. Leading Solutions: Han’s Laser vs. International Competitors

Han’s Laser has emerged as a global contender with specialized automotive solutions that balance performance and cost-effectiveness. Their HL-WH60 welding head, designed for battery tab welding, achieves 99.8% yield rates in mass production—comparable to IPG’s D85 model but with 30% lower maintenance costs.

| المعلمة التقنية | Han’s Laser HL-WH120 | Trumpf TruWeld 5000 | IPG Photonics YLR-12000 |

|---|---|---|---|

| Max Power Handling | 12kW | 15 كيلو وات | 12kW |

| Positioning Accuracy | ±0.02mm | ±0.015mm | ±0.01mm |

| Wobble Frequency | 500Hz | 1kHz | 800Hz |

| Copper Absorption | 40% (blue laser) | 35% (green laser) | 50% (green laser) |

Han’s blue laser technology (450nm wavelength) represents a significant breakthrough for EV battery welding, where copper-aluminum joints are common. This wavelength achieves 99.2% yield rates in battery pack assembly by minimizing spatter and porosity—a 40% improvement over traditional IR lasers . Meanwhile, Trumpf’s integration of digital twins has reduced parameter optimization time by 80% for new vehicle programs.

4. Global Case Studies: Automotive Applications Worldwide

4.1 Tesla’s 4680 Battery Revolution

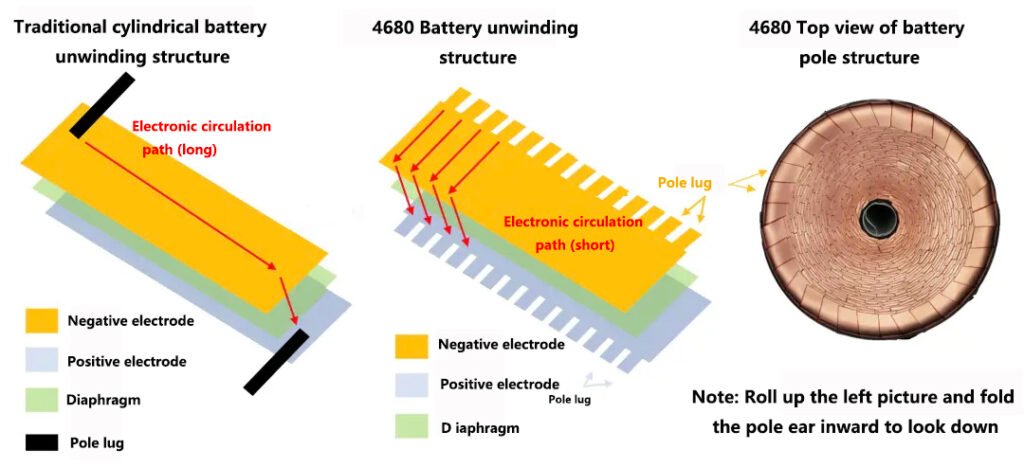

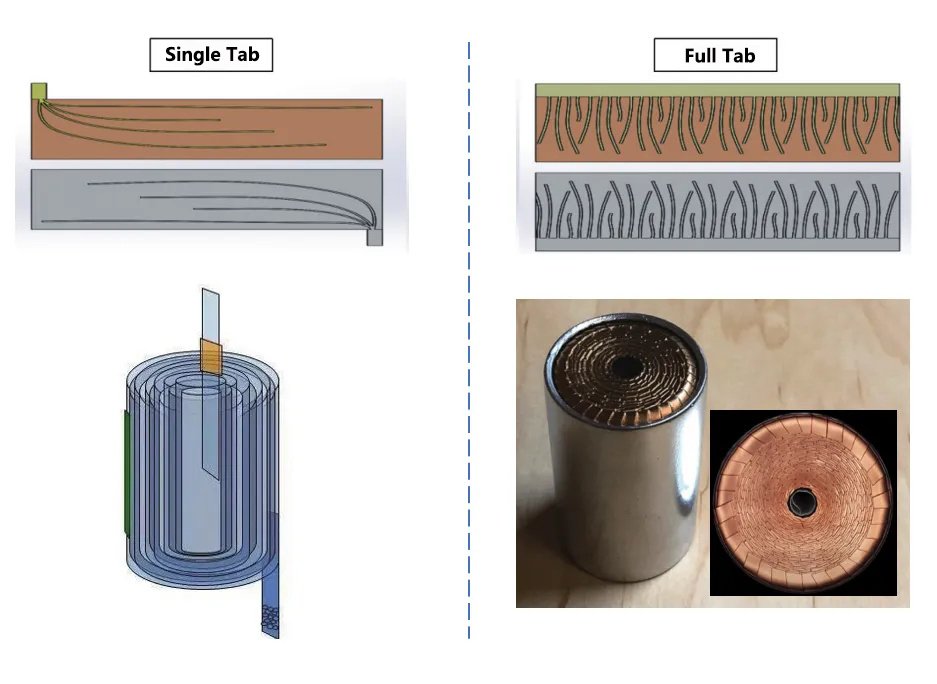

Tesla’s 4680 battery production leverages multi-axis laser welding for its structural battery pack design. Key innovations include:

- Circular tab welding with 99.9% consistency across 1,200 welds per cell

- Integrated CCD vision systems with ±0.1mm positioning accuracy

- Real-time X-ray inspection achieving <5% porosity rates

- 5-second cycle time per cell supporting 60GWh annual capacity

This implementation reduced battery pack weight by 8% while improving thermal conductivity by 15% compared to previous generations.

4.2 Volkswagen ID.4: Laser-Brazed Aerodynamics

Volkswagen employs laser brazing for the ID.4 roof joints, achieving:

- Weld seam width <0.8mm, reducing aerodynamic drag by 0.02

- Elimination of traditional PVC sealing strips, saving 1.2kg per vehicle

- 95% base material strength matching

- 34 welds completed in 13 seconds vs. 34.7 seconds with resistance welding

The process uses a 4kW fiber laser with dynamic beam shaping to manage zinc vapor in galvanized steel, reducing porosity by 92% .

4.3 BMW’s Remote Laser Welding Efficiency

BMW’s application of remote laser welding demonstrates dramatic productivity gains:

- Differential gear welding replacing bolted connections, reducing weight by 1.8kg

- Cycle time reduction from 30s (resistance spot welding) to 5s (remote laser)

- Single robot completing 34 welds that previously required 4 robots

- Noise reduction of 3dB through improved gear meshing precision

This implementation, developed in partnership with Trumpf, has been expanded across 8 vehicle platforms since 2006.

5. Technical Performance & Comparative Analysis

Laser welding outperforms traditional methods across key metrics:

| Performance Metric | Laser Welding | Resistance Spot Welding | Arc Welding |

|---|---|---|---|

| Energy Density | 10⁶-10⁷ W/cm² | 10³-10⁴ W/cm² | 10⁴ W/cm² |

| Heat-Affected Zone | <0.3mm | 2-3mm | 3-5mm |

| Welding Speed | 6-12m/min | 3-5 spots/min | 0.5-2m/min |

| Joint Strength | 85-95% of base | 70-80% of base | 75-85% of base |

| تكلفة المعدات | Higher | Lower | Medium |

| Per Unit Cost (100k units) | $6-16M | $10-22M | $8-18M |

Critical advantages for automotive applications include laser welding’s ability to join dissimilar materials (e.g., aluminum to high-strength steel) with minimal distortion, and its compatibility with automated inspection systems that ensure CPK >1.67 process capability.

6. Future Trends: Materials and Methods

The next decade will see three transformative trends:

- Wavelength Diversification: Blue/green lasers will capture 45% of EV battery applications by 2030, despite 30% higher equipment costs, due to superior copper welding performance

- AI-Driven Process Control: Neural network-based systems already predict weld quality with 98% accuracy, reducing defect rates from 0.5% to 0.1%

- Sustainability Innovations: 30kW systems reduce energy consumption by 30% annually, while modular designs enable 5-minute reconfiguration for material changes

Materials innovation is driving new applications, with laser welding now supporting:

- Aluminum alloys up to 6mm thickness in structural components

- Copper foil as thin as 0.05mm in battery current collectors

- Advanced high-strength steels (AHSS) with 1500MPa tensile strength

| Time period | Laser technologies | Materials and applications | Challenges and advancements |

| 1990s | CO2 lasers High-power CO2 lasers become widely adopted in automotive manufacturing | Steel tailored blanks The primary application is welding customized steel sheets of varying thicknesses (tailored blanks) for car bodies, leading to weight reduction | Initial adoption While effective, CO2 lasers are bulky and less efficient than modern solid-state lasers. The technology begins to replace some traditional resistance spot welding. |

| 2000s | Nd:YAG lasers High-power Nd:YAG lasers emerge, capable of transmitting beams via optical fiber | Body-in-white (BIW) Robotic 3D welding using fiber-delivered lasers is applied to BIW assembly, replacing some resistance spot welding | Limited applications High equipment cost and strict joint accuracy requirements limit Nd:YAG lasers to a narrower range of uses compared to later technologies |

| 2010s | Fiber and disc lasers Fiber lasers gain dominance due to high power, superior beam quality, and efficiency | Advanced High-Strength Steels (AHSS) The push for lightweighting and fuel efficiency drives the use of AHSS, which are welded with fiber lasers | Heat Affected Zone (HAZ) softening The high hardenability of AHSS creates challenges with HAZ softening, which is addressed by controlling welding parameters like speed and power. Lightweighting The ability to create continuous seams and reduce flange widths with laser welding further enables vehicle weight reduction |

| 2020s | Hybrid laser-arc welding Combining laser welding with traditional arc welding increases gap-bridging capabilities and stability | Dissimilar materials Joining aluminum alloys to steels and copper becomes possible using advanced techniques like beam wobbling and using filler wires. Electric Vehicle (EV) battery packs Precision fiber lasers are used to join the thin-walled components of battery modules and busbars | Dissimilar material challenges Welding dissimilar metals requires mitigating the formation of brittle intermetallic compounds (IMCs) by controlling the laser position and using intermediate materials. Copper and aluminum welding Laser welding copper connections in EV battery packs requires specialized welding techniques to handle its high thermal conductivity |

| Future (2025+) | Dynamic Beam Lasers (DBLs) DBLs offer real-time beam shaping, frequency, and focus steering for superior control. AI-integrated welding systems Systems will use AI and machine learning for real-time quality prediction, defect detection, and automated parameter adjustments | Next-gen AHSS and multi-material designs Continued demand for lighter, more efficient vehicles will drive the use of advanced AHSS and innovative multi-material architectures. Automated battery manufacturing High-speed, high-quality welding is critical for scaling up EV battery production, from modules to packs | Intelligent process monitoring Advanced process sensing and AI will monitor and optimize welding in real-time, reducing defects and improving production efficiency. High-speed welding DBL technology will overcome feed rate limitations for welding materials like aluminum, which historically resulted in porosity and cracking at high speeds |

7. Conclusion: The Road Ahead for Laser Welding

As the automotive industry navigates electrification and lightweighting challenges, laser welding has emerged as a foundational technology. Its unique combination of precision, efficiency, and material versatility—exemplified by solutions from Han’s Laser, Trumpf, and IPG—will continue to redefine manufacturing standards.

The technology’s strategic value is underscored by its role in enabling both mass production efficiency and performance breakthroughs. For manufacturers, investments in laser welding technology are no longer optional but essential to remaining competitive in a rapidly evolving global automotive market. With ongoing innovations promising even greater precision and material compatibility, laser welding’s impact on automotive manufacturing will only deepen in the coming decade.

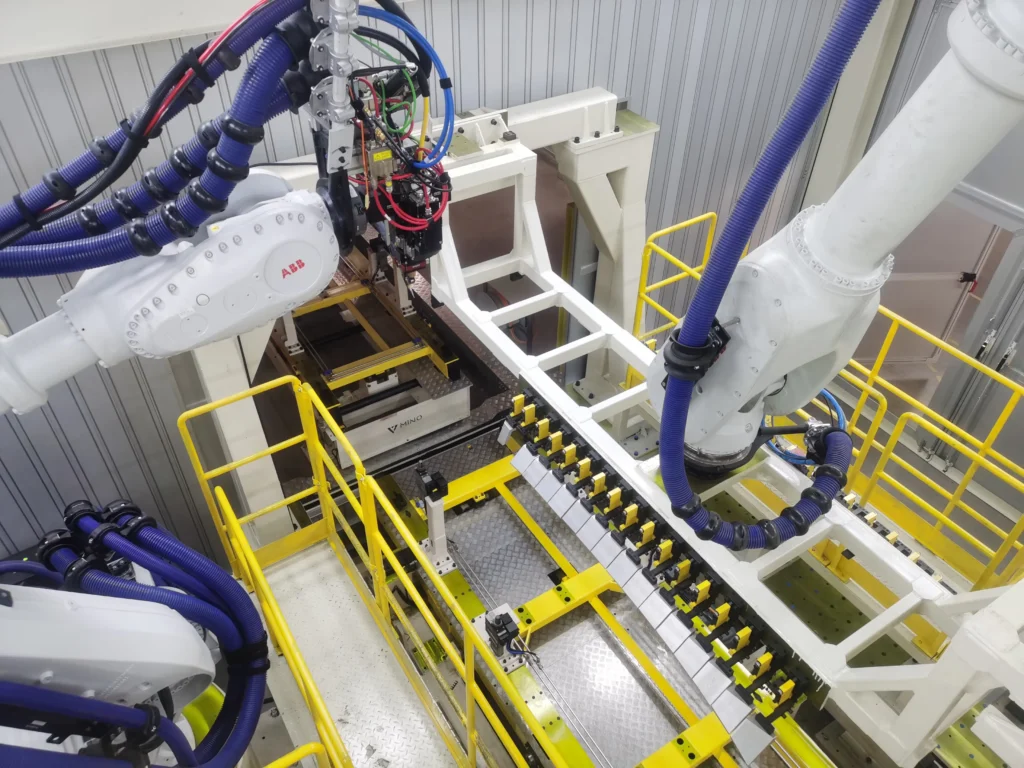

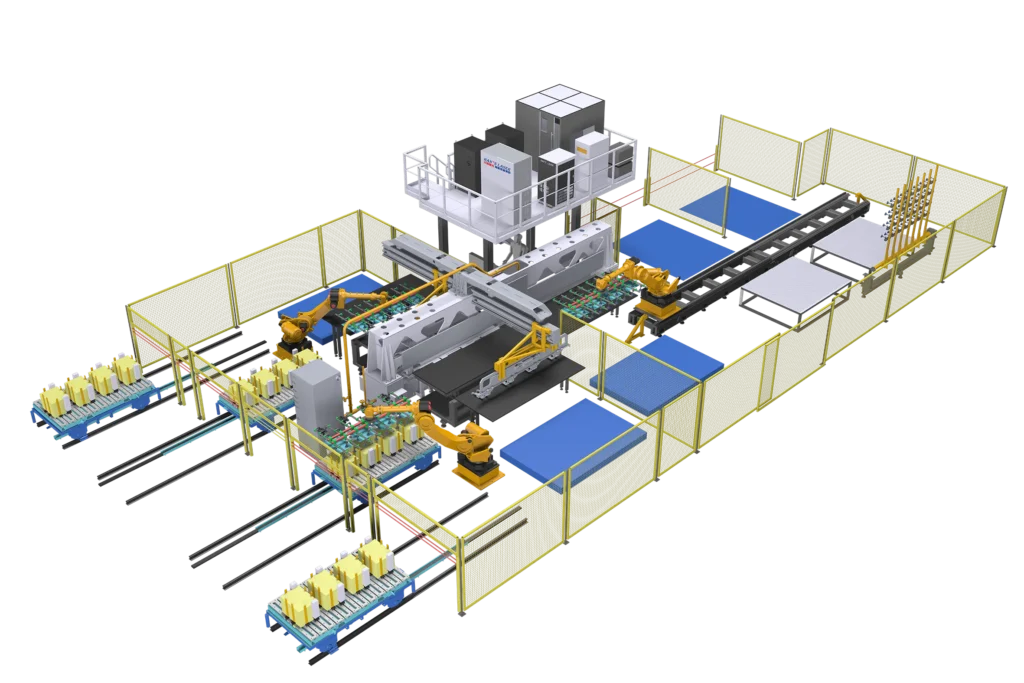

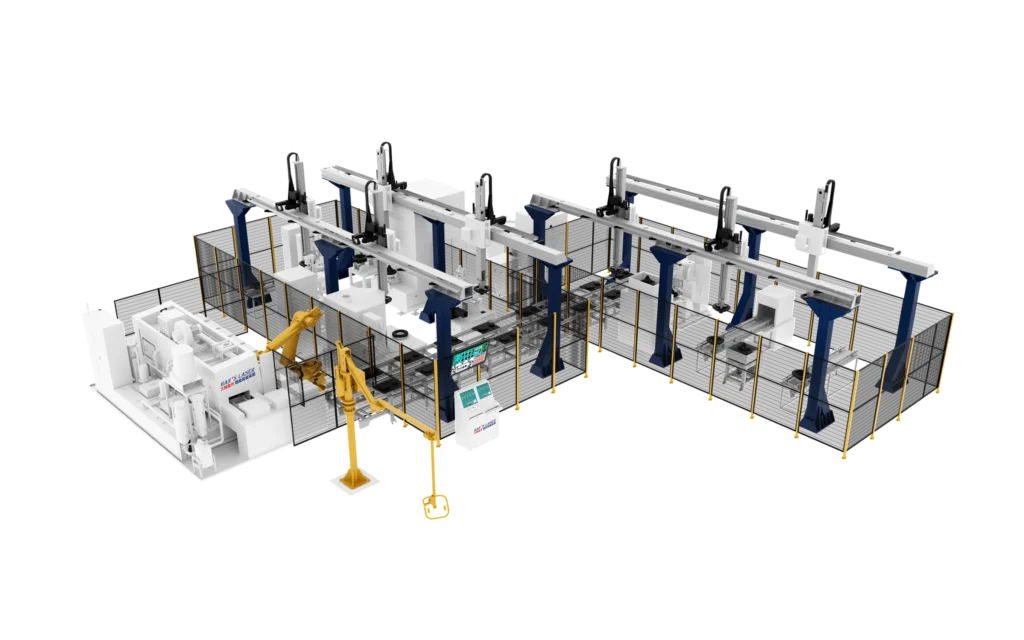

Han’s Laser Special laser welding machine for automotive industry