In the fast-paced world of manufacturing, staying ahead means embracing tools that deliver speed, precision, and efficiency. If you’re in the market for a fiber laser cutting machine, 2025 is shaping up to be an exciting year. With the global laser cutting machine market projected to reach $5.7 billion by 2025 (according to MarketsandMarkets reports), driven by advancements in AI integration and high-power capabilities, these machines are no longer just tools—they’re game-changers for industries like electronics, automotive, and medical devices.

At Shiguang Laser, we’ve been at the forefront of this evolution. As a trusted exporter of advanced laser equipment from China, we partner with leading brands like HAN’S FOCUS and OSPRI Laser to provide end-to-end solutions for cutting, weldingو precision machining. Our founding team brings over 20 years of industry experience, collaborating with more than 50 factories to offer high-precision, intelligent, and cost-effective options. Whether you’re upgrading your production line or starting fresh, this guide will walk you through everything you need to know to choose the right fiber laser cutting machine. Let’s dive in!

What is a Fiber Laser Cutting Machine and Why Choose One?

A fiber laser cutting machine uses a high-powered fiber laser to cut through materials like metal, plastic, and composites with incredible accuracy. Unlike traditional CO2 lasers, fiber lasers generate the beam through optical fibers doped with rare-earth elements, resulting in a more focused, efficient energy delivery.

Why opt for fiber over other types? Here are the key benefits:

- Superior Efficiency and Speed: Fiber lasers convert electrical energy into laser light with up to 50% efficiency, cutting materials at speeds up to 3-5 times faster than CO2 lasers. This means shorter production cycles and lower operational costs.

- Precision and Versatility: With beam diameters as small as 0.1mm, they achieve micron-level accuracy, perfect for intricate designs in IC chips or jewelry.

- Low Maintenance: No moving parts in the laser source reduce downtime, and they last up to 100,000 hours—far longer than gas lasers.

In 2025, these advantages are amplified by emerging trends. For instance, the fiber laser market is expected to grow to $4.4 billion by 2025 (as per HeatSign’s analysis), fueled by demand for processing thicker materials and integrating with smart factories.

Key Trends Shaping Fiber Laser Cutting Machines in 2025

The laser industry is evolving rapidly, and 2025 brings innovations that make fiber laser cutters even more indispensable. Based on recent reports from Hymson and Mikon Machinery, here are the top trends to watch:

1. AI and Automation Integration

AI is transforming fiber lasers into “smart” machines. Expect systems with real-time monitoring that adjust parameters automatically for optimal cuts, reducing errors by up to 30%. At Shiguang Laser, our HAN’S FOCUS models already incorporate AI-enhanced autonomous cutting, allowing seamless integration with robotics for Industry 4.0 setups.

2. Higher Power for Thicker Materials

Power levels are soaring—up to 30kW and beyond—enabling cuts through materials thicker than 50mm without compromising speed. This is a boon for automotive parts and heavy machinery. Trends from Sudalaser indicate an 8.4% CAGR through 2030, driven by these high-power advancements.

3. Enhanced Precision and Sustainability

Precision is hitting new highs with improved beam quality, minimizing heat-affected zones for cleaner edges. Sustainability is also key: Fiber lasers use less energy and produce minimal waste, aligning with global eco-standards. Cognitive Market Research notes a 3.7% CAGR in North America alone, emphasizing green tech.

4. Market Growth and Accessibility

The fiber laser cutter market is booming, valued at $2.06 billion in 2024 and projected to hit $3.19 billion by 2033 (Business Research Insights). This growth makes advanced machines more affordable, especially from Chinese manufacturers like those we partner with at Shiguang Laser.

These trends mean that investing in a fiber laser cutter now positions your business for long-term success. But how do you pick the right one? Let’s break it down.

Factors to Consider When Choosing a Fiber Laser Cutting Machine

Selecting the perfect machine isn’t one-size-fits-all. Here are the essential factors, tailored to 2025’s landscape:

1. Power and Cutting Capacity

Power determines what you can cut. For thin sheets (under 10mm), a 1-3kW machine suffices; for thicker metals, go for 6kW+. Our OSPRI Laser heads, for example, support up to 20kW, ideal for auto parts or molds.

Consider your materials: Stainless steel? Aluminum? Fiber lasers excel at reflective metals where CO2 struggles.

2. Precision and Speed

Look for machines with advanced motion systems like linear modules for ±0.03mm accuracy. In 2025, trends lean toward high-speed cutters (up to 200m/min), reducing cycle times. Shiguang Laser’s high-precision models, certified by CE and FDA, deliver this for electronics and medical equipment.

3. Software and User Interface

User-friendly software is crucial. Opt for systems with intuitive CNC controls and CAD/CAM compatibility. AI features, as highlighted in North America market strategies, allow predictive maintenance and auto-optimization.

4. Build Quality and Brand Reliability

Choose reputable brands. At Shiguang Laser, we offer HAN’S FOCUS and OSPRI Laser products, backed by national patents and global certifications. Our 50+ factory partnerships ensure robust supply chains and customization options.

5. Cost and ROI

Entry-level machines start at $20,000, but factor in long-term savings—fiber lasers cut energy bills by 50% compared to alternatives. With market growth, prices are stabilizing, making 2025 a great time to buy.

6. After-Sales Support

Don’t overlook service. We provide multi-language manuals, remote troubleshooting, and global shipping. Our 20+ years of experience mean reliable support for your investment.

Pro Tip: Calculate ROI by estimating material savings and productivity gains. For instance, switching to fiber can pay off in under a year for high-volume shops.

Real-World Applications of Fiber Laser Cutting Machines

Fiber lasers shine across industries, enabling innovation and efficiency:

- Electronics and IC Chips: Micron-precision cuts for circuit boards, reducing defects in IT digital products.

- Automotive Parts: Fast processing of chassis and exhaust systems, with trends toward hybrid manufacturing.

- Medical Equipment: Sterile, accurate fabrication for instruments, compliant with FDA standards.

- Jewelry and Crafts: Intricate designs without burrs, ideal for custom pieces.

- Aerospace and Military: High-power cuts for durable alloys, as per 2025 innovations in robotics integration.

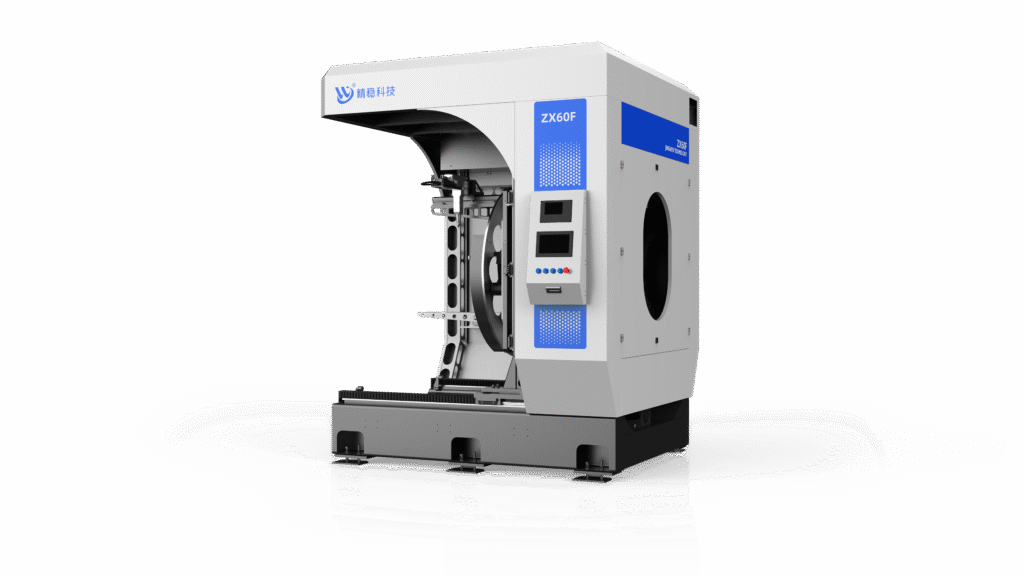

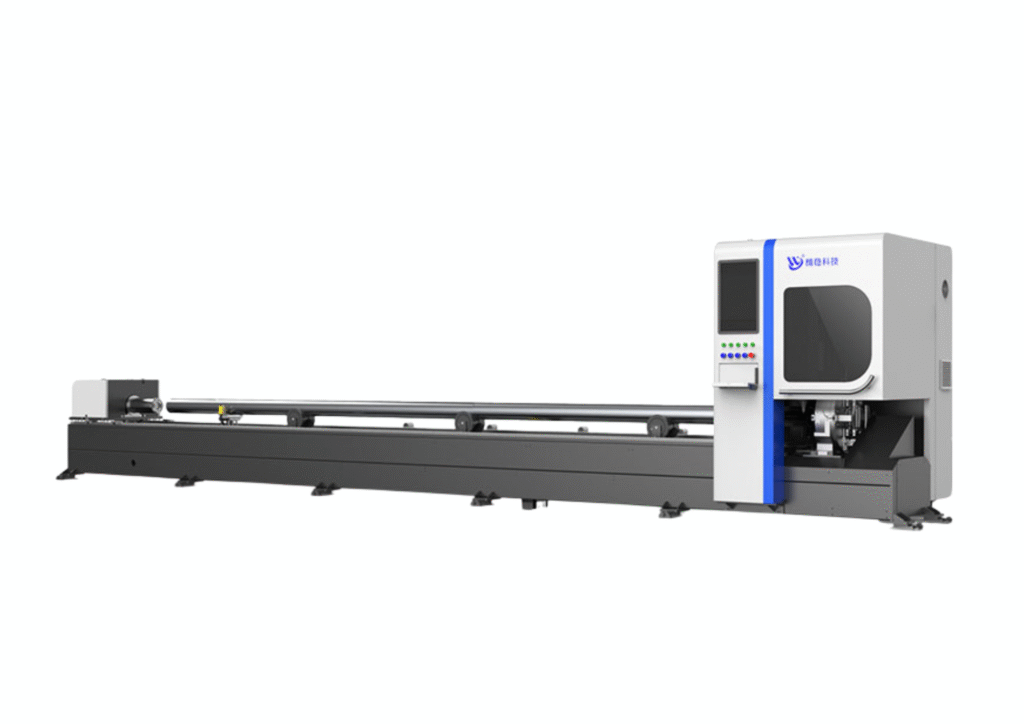

At Shiguang Laser, we’ve helped clients in these sectors upgrade with customized solutions, like our Jingwen Tech series for flexible production lines.

Maintenance and Best Practices for Longevity

To maximize your machine’s lifespan:

- Daily Checks: Clean lenses and nozzles to prevent buildup.

- Regular Calibration: Use software tools for beam alignment.

- Preventive Maintenance: Schedule professional servicing; our team offers this globally.

In 2025, smart diagnostics via AI will make this easier, predicting issues before they arise.

Conclusion: Make the Right Choice with Shiguang Laser

Choosing a fiber laser cutting machine in 2025 boils down to aligning your needs with the latest trends—AI, high power, and sustainability. At Shiguang Laser, we’re here to guide you. Our range, from HAN’S FOCUS heads to full OSPRI systems, ensures you get intelligent, cost-effective solutions backed by expertise.

Ready to upgrade? Contact us today for a free consultation and customized quote. Email Grace at grace@shiguanglaser.com or visit our Contact Page. Let’s enable your manufacturing success!