Laser welding has emerged as a transformative technology in industrial joining processes. It offers distinct benefits over traditional methods such as TIG or MIG welding, particularly in applications that demand high precision, minimal thermal distortion, and increased productivity. For procurement professionals evaluating advanced joining technologies, laser welding provides both measurable performance improvements and significant cost advantages.

Core Principle of Laser Welding

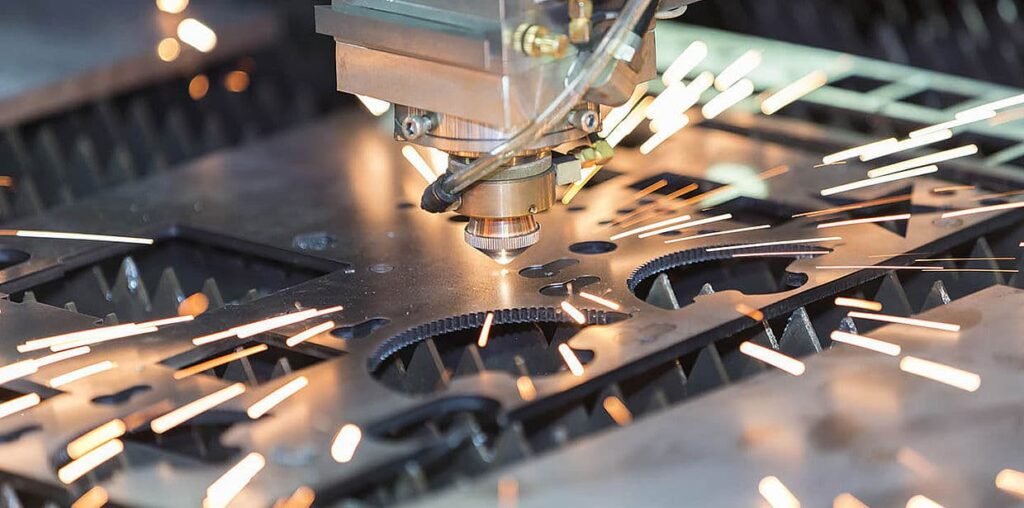

Laser welding works by directing a high-intensity laser beam onto a material surface, where it is absorbed and converted into heat. This heat causes localized melting and, in some cases, vaporization and plasma formation. Depending on the heat input and material response, laser welding is typically categorized into two modes:

- Conduction Welding: Heat causes the material to melt but not vaporize. It is suitable for thin sections and produces smooth welds with minimal penetration.

- Keyhole (Deep Penetration) Welding: The material melts and vaporizes, forming a narrow, deep keyhole that enables high aspect ratio welds. This method is the dominant mode in industrial applications.

Technical Advantages

1. Superior Weld Quality

Laser welding offers tight heat control, resulting in narrow heat-affected zones (HAZ), rapid cooling, and minimal warping. The welds are clean, with fine microstructures and mechanical properties close to that of the base material. Fine grain size and reduced dislocations help ensure consistent strength and durability.

2. Increased Efficiency and Throughput

Compared to TIG or MIG welding, laser welding is 5 to 10 times more efficient in many applications. Its high-speed operation, combined with minimal rework and post-processing requirements, dramatically reduces production time. This is particularly advantageous in the stainless steel tube industry, where straight-seam laser welding has become standard practice.

3. Greater Design Flexibility

Laser welding is a non-contact process, meaning the laser head does not need to physically touch the workpiece. This allows for greater access in complex geometries, enabling welding of hard-to-reach seams, internal joints, and contoured surfaces. For example, laser welding can be used on internal turbine components or tightly packed sensor assemblies where arc welding would be impractical.

4. Exceptional Precision

Laser welding is ideal for small, delicate components such as sensors, valves, and battery tabs. Arc welding often generates too much heat for such fine applications. In contrast, laser welding delivers high aspect ratio welds (depth-to-width), making it suitable for deep penetration welding in medium to thick plates while maintaining excellent control.

Cost Reduction and Process Simplification

Laser welding contributes to lower manufacturing costs in several key ways:

- Thin Sheet Welding: Reduced distortion minimizes the need for realignment or scrap, while higher welding speeds cut down labor costs.

- Medium-Thick Plate Welding: Eliminates the need for beveling and reduces post-weld surface finishing. This translates to up to 40% time savings and over 30% cost savings compared to traditional arc welding.

Moreover, laser welding does not require electrodes, avoiding issues of electrode wear or contamination. The reduced tooling wear and minimal consumables further contribute to lower total cost of ownership.

Versatility and Material Compatibility

Laser welding supports a wide range of metals and dissimilar material combinations. Automated robotic integration allows for precise, repeatable welds even at difficult angles. The ability to operate at a distance and use optical guidance systems enables welding in constrained or obstructed spaces—something few traditional welding methods can achieve.

Current and Emerging Applications

Laser welding is now a core technology in several sectors:

- Power Batteries: Used for welding battery tabs, terminals, sealing pins, and connectors due to its precision and repeatability.

- Automotive Components: Employed in the production of gears, drive units, and structural parts.

- Rail and Shipbuilding: Enables deep penetration and long seam welding.

- Aerospace and Defense: Used for lightweight, high-strength assemblies requiring tight tolerances.

Thanks to rapid localization and price declines in laser sources, particularly from Chinese manufacturers such as Raycus and MaxPhotonics, equipment costs have fallen sharply. A 2kW laser source that once cost 10–15W RMB per unit in 2017 now sells for 2–3W RMB—an 80% price drop.

The range of processable materials continues to expand. While stainless steel and aluminum alloys are the current mainstays, laser welding is rapidly advancing into carbon steels and high-strength steels, replacing older TIG and CMT techniques.

الخاتمة

Laser welding is reshaping the landscape of precision manufacturing. With unmatched precision, minimal distortion, and cost-efficiency, it presents a compelling option for manufacturers seeking to modernize their joining processes. As equipment costs continue to decline and adoption broadens across industries, laser welding is poised to become the new standard for high-performance industrial fabrication.