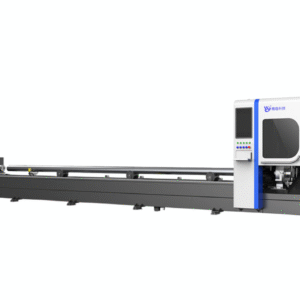

The T9/T9Pro/T12/T12Pro from the T Series is a high-speed 3D fiber laser tube cutting machine built for precision, speed, and versatility. It supports various tube shapes—round, square, rectangular, and special profiles—with a processing diameter of Φ5–120mm and length up to 6500mm. Powered by 1000W to 6000W fiber lasers, it achieves ±0.15mm precision while minimizing tailing to just 40–60mm. Key highlights include a movable front chuck, ultra-short tailing, bus-type CNC system, and rapid loading time. It’s a compact yet powerful solution for efficient cutting of stainless steel, aluminum, carbon steel, and more—perfect for manufacturers seeking fast turnaround and lower material waste.

The T Series High-Speed 3D Fiber Laser Tube Cutting Machine—covering models T9, T9Pro, T12, and T12Pro—is engineered for high-precision cutting of small to medium-sized metal tubes. With laser power options ranging from 1000W to 6000W, this machine is tailored to meet the diverse needs of modern manufacturing, from furniture and fitness equipment to automotive and aerospace components.

Designed to handle round, square, rectangular, and waist-shaped tubes, the T Series supports an effective cutting diameter of Φ5–120mm for round tubes and 5×5mm to 120×120mm for square tubes. The machine offers exceptional flexibility, thanks to a maximum processing length of ≤6500mm and a tailing length as short as 40–60mm—ideal for minimizing material waste.

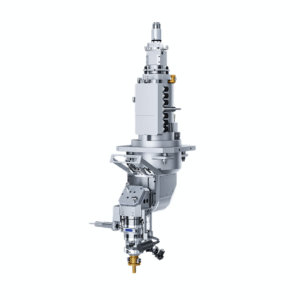

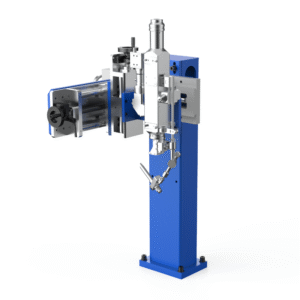

At the heart of the system is a precision chuck that ensures ultra-short tailing, paired with a movable front chuck and advanced bus-type CNC control system. These components allow for ultra-high-speed machining, maintaining ±0.15mm processing precision across all compatible materials, including stainless steel, carbon steel, aluminum, copper, and iron.

What makes the T Series particularly production-friendly is its optimized loading structure, enabling super short material loading time and maximizing throughput. The equipment’s dimensions (approximately 9400×2400×2300mm) are compact enough to fit into standard industrial workshops, while still offering industry-grade capabilities.

This all-in-one solution not only delivers clean, fast, and consistent cuts but also drastically reduces setup time and operational costs—making it a highly cost-effective tool for pipe cutting applications. Whether you’re scaling up production or upgrading from manual processes, the T Series helps streamline operations without compromising quality or speed.

Laser Power Options: 1000W to 6000W (Optional)

Cutting Precision: ±0.15mm

Max Tube Length: ≤6500mm

Cutting Range: Φ5–120mm (Round), 5×5mm–120×120mm (Square)

Supported Tube Types: Round, Square, Rectangular, Waist-Shaped

Supported Materials: Stainless Steel, Carbon Steel, Aluminum, Copper, Iron

Compact Equipment Size: ≈9400×2400×2300mm

CNC Control System: Bus-type for fast response and stability

Model | T-T9/T9Pro/T12/T12pro |

|---|---|

Laser Power | 1000-6000W(Optional) |

Processing Precision | ±0.15mm |

Tailing length | 40~60mm |

Equipment dimensions | ≈9400x2400x2300mm |

Cutting Diameter of Round Tube | Φ5~120mm |

Cutting Diameter of Square Tube | 55mm~120120mm |

Maximum length of machined pipe | ≤6500mm |

Cutting Material | Stainless Steel, Carbon Steel, Aluminum, Copper, Iron |

Cutting Tube Type | Round Tube, Square Tube, Rectangular Tube, Waist-Shaped Tube |

Product Categories

Featured Products

Related Products

Resource

Phone / Wechat

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

Address

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Company

Contact

+86 17872326554

Grace@shiguanglaser.com

+86 13671610612

3rd Floor, Building A, Runchang Industrial Park, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2025 Shenzhen Shiguang Laser Equipment Co., Ltd. All rights reserved.